Serfilco horizontal PUMPS

hORIZONTAL pUMPS

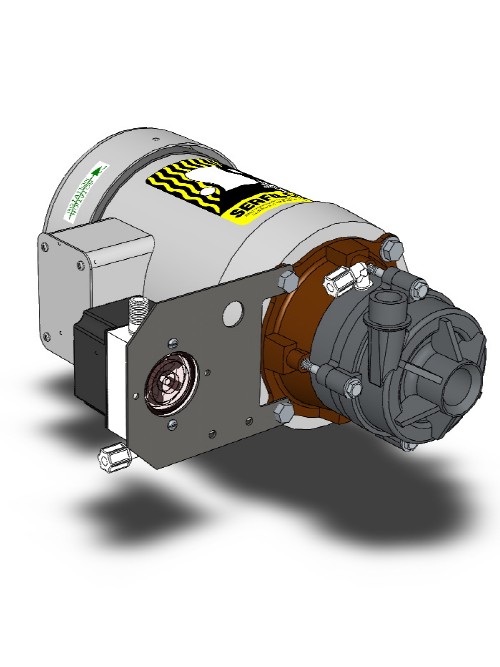

SERIES ‘HC’ HORIZONTAL PUMPS

Specifications

Series ‘HC’ pumps have 1″ FNPT suction x 3/4″ MNPT discharge and are available in CPVC or 100% PVDF. Series ‘HK’ pumps have 1 1/2″ MNPT suction x 1 1/2″ MNPT discharge and are available in CPVC with PVDF suction casing or 100% PVDF. Standard elastomers are FKM, EPDM is available. All models utilize a molded, semi-enclosed impeller. Mechanical seal is Type 21, externally mounted with SS components not in solution contact. Double mechanical seal is designed for flushing the seal chamber with water and is recommended for applications where abrasives or salts are present, or for conditions where metal deposition will occur. In addition, double water flush sealed pumps will permit dry run operation. Standard mechanical seal faces are silica-free ceramic/carbon (M1) and (M2). Silicon carbide seal faces (M8) are available and recommended for critical applications. Motors are chemical duty with sealed oversize earings, cast iron end bells, two-part epoxy finish, and SS tag. Motors are rated with 1.15 service factor at 50 or 60 Hz.

fEATURES:

• Flows to 78 gpm or 53′ TDH @ 60 Hz

• Non-metallic solution contact – CPVC or 100% PVDF

• Single or double mechanical seal Carbon/ceramic or silicon carbide EPDM or FKM elastomers

• Centrifugal – quiet, vibration-free

• Standard models provide non-overloading full flow with liquids to 1.2 S.G.

• Chemical duty motor (1/3 – 1-1/2 HP

Material:

CPVC, PVDF

Performance:

10-70 gpm

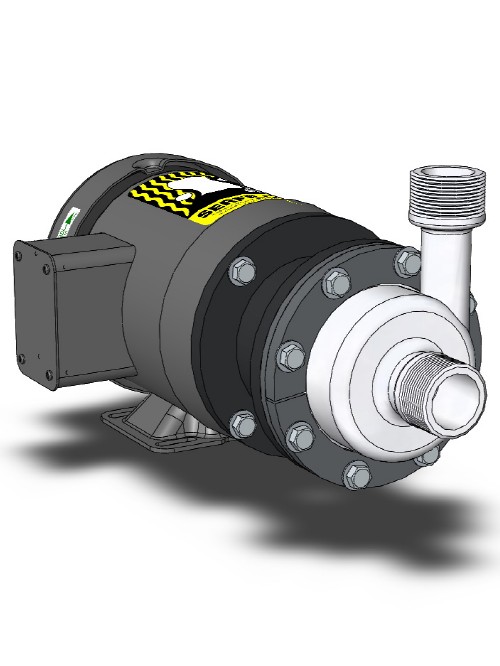

SERIES ‘HK’ HORIZONTAL PUMPS

Specifications

Series ‘HK’ Horizontal Pumps feature “total” chemical resistance with non-metallic construction of all wetted components. The molded, semi-enclosed impellers are designed to provide maximum pumping efficiency. These pumps feature external single seal or double water-flushed mechanical seal with choice of EPDM or FKM elastomer materials. Available close-coupled to minimize size or long-coupled with bearing pedestal base plate and motor. All closecoupled pumps are driven by chemical duty motors suitable for continuous duty in corrosive environments. Pumps are ideal for transferring and recirculating industrial solutions, plating solutions, process chemicals and other fluid handling applications.

fEATURES:

Flows to 78 gpm or 53 FT. TDH @ 60 Hz

• Non-metallic solution contact – CPVC or 100% PVDF

• Single or double mechanical seal

• Centrifugal – quiet, vibration-free

• Standard models provide non-overloading full flow with liquids to 1.2 S.G.

• Chemical duty motor (1/3 – 1-1/2 HP)

Material:

CPVC, PVDF

Performance:

10-70 gpm

SERIES ‘HH’ HORIZONTAL PUMPS

Specifications

Series ‘HH’ pumps are molded of natural CPVC or natural PVDF. They feature a volute designed for high TDH at high efficiency and all around optimum performance. The unique sleeved impeller design and non-metallic internally mounted mechanical seal combine to provide a compact assembly offering nonmetallic solution contact. Five impeller diameters provide a full range of flow and head performance with efficient use of motor horsepower. Motors are standard NEMA 56C, TEFC. For explosion-proof motors, consult Sales Department.

Pedestal mounted pump assemblies are available for 1/2 to 5 HP standard end bell motors. An optional long-coupled kit includes cast iron bearing, pedestal frame, flexible coupling, guard and FRP mounting channel.

fEATURES:

• Flows to 68 gpm or 167 ft. TDH @ 60 Hz

• Non-metallic solution contact CPVC, PVDF

• Single mechanical seal

• Connections: 1″ MNPT inlet and 3/4″ MNPT outlet

• Maximum solid size – .15″ (3.8mm)

mATERIAL:

CPVC, PVDF

Performance:

10-60 gpm

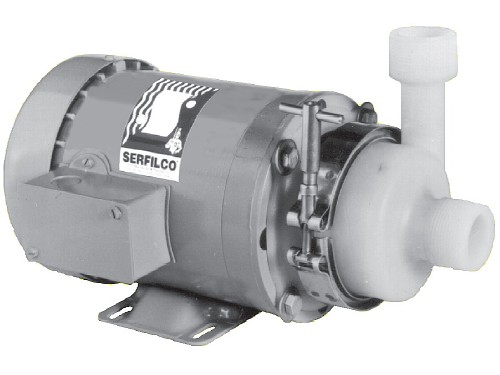

SERIES ‘K’ HORIZONTAL PUMPS

Specifications

Series ‘K’ centrifugal pumps are molded of high purity 100% natural color virgin PVDF. The resin is FDA approved and offers exceptionally high chemical resistance to strong acids and solvents. Semi-enclosed impeller provides efficient, trouble-free operation at all operating temperatures. Inlet and outlet connections are 1 1/2″ MNPT or sanitary flange. Unique design of carbon/ceramic mechanical seal isolates SS shaft from solution contact. The available (M3) seal component is silica-free ceramic which allows the pump to be used for solutions which contain fluorides . Seal elastomers and casing O-Ring are FKM. Casing clamp with “T” handle lock allows choice of discharge direction and ease of pump disassembly.

Features:

• Non-metallic solution contact 100% natural color PVDF for temperatures to 280°F (138°C)

• 1 1/2″ MNPT or sanitary connections

• Mounts to 56J motor

• Ideal for OEM applications

• Casing clamp for easy disassembly Provides choice of discharge direction

• To 80 gpm or 51 FT. TDH @ 60 Hz (252 LPM or 10.8m @ 50 Hz)

• Seal can be changed in 5 minutes

Material:

PVDF

Performance:

10-80 gpm

SERIES ‘HN’ HORIZONTAL PUMPS

Specifications

The Series ‘HN’ pump is capable of “total” chemical resistance, both internally and externally with its non-metallic construction of all wetted components. Engineering grade thermoplastics provide application compatibility with a variety of chemicals that would be corrosive to other materials of construction.

The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow/head requirements. The unique mechanical seal eliminates any metal in contact with the solution pumped. All of these features allow this pump to properly handle many applications at a fraction of the cost of exotic alloys.

Features:

• Non-metallic solution contact 30% glass-filled Noryl

• To 135 gpm or 88 ft. TDH @ 60 Hz

• Single mechanical seal carbon / silica-free ceramic EPDM or FKM elastomers

• Centrifugal – quiet, vibration-free

• Standard NEMA C face 56J TEFC motor

• 1 1/2″ x 1 1/2″ FNPT connections

• Back pull-out design, easy assembly and maintenance

Material:

Noryl

Performance:

20-120 gpm

SERIES ‘HE’ HORIZONTAL PUMPS

Specifications

The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow/head requirements.The external mechanical seal and impeller sleeve design isolates metal components to provide non-metallic solution contact with the pumped solution. The standard (M8) seal assembly has silicon carbide seal faces and is the most durable and longest lasting mechanical seal available. The double mechanical seal models require water lubrication of the seal faces and allows the pump to be used for solutions containing abrasives, high salt concentrations and for electroless plating solutions. Standard models are constructed of CPVC, PP, PVDF or ECTFE with threaded connections. Elastomers are EPDM or FKM. The mechanical seal is type 21, externally mounted with SS components not in solution contact. A double mechanical seal is recommended for solutions containing abrasives and for high temperature or other critical service. Close coupled motors are NEMA ‘JM’ or metric (IEC) standard. The motors designated NEMA can operate on 50 or 60 Hz at full rated horsepower.

Features:

• Flows to 175 gpm or 130′ TDH @ 60 Hz

• Non-metallic solution contact PPP, CPVC, PVDF or ECTFE

• Single or double mechanical seal

• Centrifugal – quiet, vibration-free

• NPT or metric connections available

• Chemical duty motor

Material:

PP, CPVC, PVDF, ECTFE

Performance:

20-175 gpm

SERIES ‘HF’ HORIZONTAL PUMPS

Specifications

The Series ‘HF’ Horizontal pump represents the next generation of molded pumps from SERFILCO. The ‘HF’ retains a robust design and non-metallic solution contact to meet the most demanding applications while providing the choice of materials of construction and economy found in all of our molded pumps. The ‘HF’ is offered in a choice of our exclusive PPP high temperature polypropylene or CPVC construction and is ANSI dimensional with the optional flanged connections. The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow and head requirements. The external mechanical seal and impeller sleeve design isolates metal components to provide non-metallic solution contact with the pumped solution. The standard (M8) seal assembly has silicon carbide seal faces and is the most durable and longest lasting mechanical seal available. The double mechanical seal models require water lubrication of the seal faces and allows the pump to be used for solutions containing abrasives high salt concentrations and for electroless plating solutions.

Features:

• Non-metallic solution contact

• PPP high temperature polypropylene, CPVC or PVDF

• Centrifugal, quiet, vibration free

• Single or double mechanical seal with EPDM or FKM elastomers

• Chemical duty motor

• ANSI dimensional – with optional flanged connections

Material:

CPVC, PP, PVDF

Performance:

50-400 gpm

SERIES ‘H’ HORIZONTAL PUMPS

Specifications

The Series ‘H’ pump is a heavy-duty centrifugal pump machined from solid CPVC. It provides a high

level of resistance to aggressive chemicals. An external mechanical seal and sleeved shaft* provide excellent corrosion resistance. The new Series ‘H’ 6″ x 4″ pump features a titanium or Hastelloy C shaft. The Series ‘H’ pump serves as an economical alternative to ANSI style process pumps. The high flow rates, chemical resistance and durability of this pump make it the perfect workhorse for waste treatment, chemical processing, transfer and filter pumping. Pumps are available for long-coupling in the field to user supplied standard motors. Double seals are available and recommended forflushing the seal faces when abrasives are present or positive product containment is required. Optional coupling arrangements, mechanical seals, fittings and flange connections ensure adaptability to custom applications.

fEATURES:

• High flow rates Over 1200 gpm, or 149 ft. TDH @ 60 Hz (3800 l/min or 31.5m @ 50 Hz)

• Excellent chemical resistance Machined from solid CPVC

• Single or double mechanical seal Silicon carbide EPDM or FKM elastomers

• Quiet, vibration free Centrifugal, high efficiency enclosed impeller

• Flanged or NPT ports:

• Long or close-coupled Back pull-out design. Optional long-coupled kit available

• Standard chemical duty motors (3 – 30 HP)

• Sealed oversized bearings, cast iron end bells, shaft slinger washer, corrosion resistant twopart epoxy

Material:

CPVC

Performance:

1200 gpm

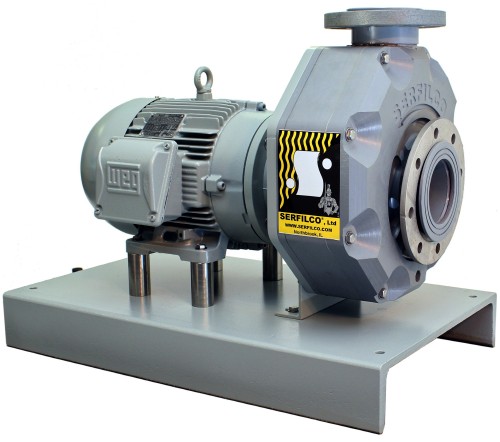

SERIES ‘HA’ HORIZONTAL PUMPS

Specifications

The Series ‘HA’ is a heavy-duty, ANSI dimensional horizontal pump engineered for utmost reliability in severe chemical applications. The pump is machined from solid CPVC and utilizes an externally mounted mechanical seal. The 3x2x6 and 4x3x8 pumps have sleeved shafts for non-metallic solution contact while the 4x3x10 and 6x4x10 pumps utilize titanium or Hastelloy C shafts. This proven design provides excellent resistance to aggressive chemicals as well as economical and reliable operation for many years of service. The Series ‘HA’ horizontal pump is available in four sizes with flow rates to 1200 gpm (3800 LPM), and is available with single or double mechanical seals and EPDM or FKM elastomers. Larger sized pumps designed to achieve 2400 gpm are in development. The standard configuration for these pumps is close coupled, however certain models are available long-coupled. The Series ‘HA’ pump with its high flow rates, chemical resistance and durability makes it the perfect “workhorse” for chemical processing, transfer and filter pumping, fume scrubbers and cooling towers or for waste treatment applications.

Features:

• Flows to 1200 gpm or 155′ TDH @ 60 Hz

• Excellent chemical resistance

• Machined from solid CPVC

• Centrifugal, quiet, vibration free

• Single or double mechanical seal with EPDM or FKM elastomers

• Long or close-coupled

• Chemical duty motor

Material:

CPVC

Performance:

100-1200 gpm

SERIES ‘HCI’ HORIZONTAL PUMPS

Specifications

The Series ‘HCI’ horizontal pumps feature compact close-coupled design. A high efficiency semi-open impeller allows for less clogging and quick cleaning. Since the components are cast, there are no welds to break. Also, cast construction provides a superior corrosion resistance over similar welded styles. The Series ‘HCI’ pumps feature the most widely accepted industrial mechanical seal designated as Type 21. This seal is mounted “inboard” and, thus tends to be self-cleaning. The seal is available as a single seal solution flush or as a double seal which uses external liquid as a flush. By adding the double seal, these pumps can better handle abrasives / salts and be protected from running dry. Pumps are constructed of cast iron for maximum corrosion resistance. Gasket is a synthetic fiber with cast iron. Both the single and double inboard seal assemblies are available in either EPDM or FKM. Double seal is recommended for flushing the seal chamber with water when abrasives are present or for certain other critical conditions. The SS shaft adapter protects the motor shaft and allows the use of standard NEMA motor. Motors are 3450 RPM @ 60Hz or 2850 RPM @50 Hz, TEFC or EXP. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 160 U. S. gpm or 90 ft. TDH @ 60 Hz (510 LPM or 19.5m @ 50 Hz)

• Cast iron solution contact

• Single or double mechanical seal Carbon/ceramic FKM or EPDM elastomers

• SS 316 shaft adapter

• Centrifugal, quiet, vibration-free

• Includes steel mounting base

• Motors are standard NEMA ‘C’ face TEFC or explosion-proof

Material:

Cast iron, Cast SS316

Performance:

10-160 gpm

SERIES ‘HSS’ HORIZONTAL PUMPS

Specifications

The Series ‘HSS’ horizontal pumps feature compact close-coupled design. A high efficiency semi-open impeller allows for less clogging and quick cleaning. Since the components are cast, there are no welds to break. Also, cast construction provides a superior corrosion resistance over similar welded styles. The Series ‘HSS’ pumps feature the most widely accepted industrial mechanical seal designated as Type 21. This seal is mounted “inboard” and, thus tends to be self-cleaning. The seal is available as a single seal solution flush or as a double seal which uses external liquid as a flush. By adding the double seal, these pumps can better handle abrasives / salts and be protected from running dry. Pumps are constructed of SS 316 for maximum corrosion resistance. Gasket is PTFE with SS 316. Both the single and double inboard seal assemblies are available in either EPDM or FKM. Double seal is recommended for flushing the seal chamber with water when abrasives are present or for certain other critical conditions. The SS shaft adapter protects the motor shaft and allows the use of standard NEMA motor. Motors are 3450 RPM @ 60Hz or 2850 RPM @50 Hz, TEFC or EXP. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 160 U.S. gpm or 90 ft. TDH @ 60 Hz

• All SS 316 solution contact

• Single or double mechanical seal Carbon/ceramic FKM or EPDM elastomers

• SS 316 shaft adapter

• Centrifugal, quiet, vibration-free

• Includes steel mounting base

• Motors are standard NEMA ‘C’ face TEFC or explosion-proof

Material:

Cast SS316

Performance:

10-160 gpm

SERIES ‘RC’ HORIZONTAL PUMPS

Specifications

The Series ‘RC’ horizontal pump is a compact close-coupled design. A high efficiency, semi-open cast iron impeller allows for less clogging and quick cleaning. The components are cast so there are no welds to break. In addition, the cast iron construction provides improved corrosion resistance over similar welded styles. The Series ‘RC’ pump is available with a choice of mechanical seals, Type 21 single or double. The seal is mounted “in-board” and, thus tends to be self-cleaning. It is available as a single seal solution flush or as a double seal which requires external liquid to flush. When ordered with a double seal, the pump will better handle abrasives, solutions which tend to crystallize, and dry run operation. Series ‘RC’ pumps are constructed of cast iron with a synthetic fiber gasket. Standard pumps feature EPDM or FKM elastomers with ceramic and carbon seal faces. These pumps use a standard NEMA C face motor. Motors are TEFC, 3450 RPM @ 60 Hz or 2850 RPM @ 50 Hz.

Features:

• Flows to 420 gpm or 82 ft. TDH @ 60 Hz (1325 LPM or 17.4m @ 50 Hz)

• SS 316 shaft, cast iron mounting bracket

• Single or double mechanical seal Carbon/ceramic EPDM or FKM elastomers

• Centrifugal, quiet, vibration-free

• Motors are standard NEMA C face, TEFC

Material:

Cast Iron

Performance:

50-400 gpm