American Plating Power

- Current ranges up to 100,000 Amps and DC voltages up to 900 VDC.

- Cooling methods include air, water, or oil cooled.

- Global leader in large scale switch mode technology with sizes up to 30000 Amps.

SCR rectifiers

Air cooled SCR rectifier

Our air cooled silicon rectifier, with primary thyristor controlled is featured with voltage and current control function. The unit is cooled by a forced air cooling system achieved by the integrated low noise emission fan. The rectifier is integrated into a solid cabinet and is intended for remote control (0 – 10 V). One of the outstanding features of the offered technology is the low noise fan design. Instead of a high volume fan, this rectifier is featured with a special air guiding system and special fan design, which prevents dripping solution from entering the cabinet. The required cooling air will be guided into the cabinet from the sides. The rectifier is rated for continuous, full load, industrial operation without any reduction in output power.

oil cooled scr rectifier

Our natural oil cooled silicon rectifier, with secondary thyristor adjustment, is integrated into a robust oil tank and is intended for remote control operation. The adjustment of the rectifier can be carried out electronically via analog signals (0-10Vdc) for constant current and voltage control. It is rated for continuous, full load, industrial operation without any reduction in output power. The rectifier is enclosed in a tough, corrugated oil tank which fulfills all of the requirements up to a NEMA 4/IP 56. This housing is ideal for installation in the most aggressive of environments, as is the cooling method. With oil cooling, there is no need for cooling air to be drawn through the internal components, which prevents depositing of any contaminants (especially dust) into the rectifier section.

water cooled scr rectifier

Our complete water cooled, thyristor controlled high power rectifier, is designed for water cooling. The rectifier is featured with a specially designed combination inverter and rectification circuit to reduce the total losses of the semiconductors, which results in lower operation costs. The rectifier is integrated into a special designed cabinet and is intended for remote control via analog signals (0 – 10V). This unit has been built into a special, robust cabinet. The lacquered housing consists of a steel frame and base. A maintenance friendly, modular construction neatly rounds off the concept of this rectifier. For maximum efficiency, all internal conductors, as well as the transformer windings, are exclusively made out of copper. The total water-cooling system for this rectifier has been specially designed. It ensures complete, efficient cooling, allowing over 90% of all generated heat losses to be removed directly by the cooling water. For this reason, the surrounding increase in air temperature is negligible in comparison with other systems, notably oil and air. The connections for cooling water entry and exit are located on the back side of the enclosure. The best water to be used for cooling is any which has the same properties as tap water – exact details can be found in the following cooling-water specification.

switch mode power supplies

The Switchmode Power Supplies (MS-Series) feature constant voltage and current control with easy, quick installation and maintenance. The output capabilities on these modular rectifiers can be expanded upon by means of parallel connection. All models have DC short circuit protection.

- High efficiency

- Power factor up to 99 %

- Ripple < 1 … 3 %

- Constant voltage and current control

- High control accuracy 1/2 19“–19“ plug-in or module

- Fan speed control

- Integrated EMC filter

- Duty factor 100 % (24/7)

- Analog interface: 0–10 V (except MSA 0025, 0050)

Options:

- Pulse operation

- Polarity reversal function

- Ramping function

- Ampere-hour meter

- Digital interface: Modbus, Profibus, Ethernet

reverse pulse power supplies

AxD Compact S

Power supply used to generate a bipolar high current waveform. The number of controllable power outputs of each unit can vary between 1 and 2. The multi-anode version (2 outputs) has proven to be a great advantage in the implementation of large pulse applications. The design of AxD power supplies differ from similar equipment, resulting in higher reliability and flexibility. In addition, the ECM and PECM version power supplies contain a higher power capacity to complete the product range. AxD Compact Power Supplies are available with air cooling.

Features:

- 1-2 Controllable outputs per device

- Available with air cooling

- Process data is displayed real time

- Guaranteed pulse repeatability

AxD Compact

The number of controllable power outputs of each unit can vary between 1 and 4. The multi-anode version (4 outputs) has proven to be a great advantage in the implementation of large pulse applications. The design of AxD power supplies differ from similar equipment, resulting in higher reliability and flexibility. In addition, the ECM and PECM version power supplies contain a higher power capacity to complete the product range. AxD Compact Power Supplies are available with air or water cooling. By using the specialized batch feature, the required recipe program can be chosen and started. At the same time all process data is displayed real time. Thus, the combination of AxD Power Supplies and VPC-Software guarantees a repeatability of results even for complex processes.

Features:

- 1-4 controllable outputs per device

- Available with air or water cooling

- Process data is displayed real time

AxD Cabinet Series

he Cabinet Series is the most powerful alternative of the AxD Series. Output currents are scalable between 400 and 10,000A. The quantity of controllable power outputs of each unit can vary between 1 and 8. Mainly the multi-anode operating (8 outputs) has proven to be a great advantage in the installation of large pulse power. In power AxD PPR Power Supplies differ from standard devices. Besides, the specific power supplies ECM and PECM containing an additional power capacity complete the product range. AxD Cabinet Series power supplies are available with air or water cooling. By using the specific monitor the required treatment program can be chosen and started. At the same time all information is displayed online. Thus, the combination of AxD Power Supplies and VPC Software can guarantee a repeatability of results even in complex processes.

Features:

- 1-8 Controllable outputs per device

- Available with air or water cooling

- Guaranteed repeatability

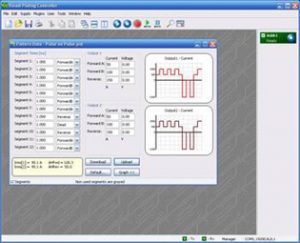

Visual Plating Controller

PC-based operating interface (HMI) for programming, monitoring, administration of programs and storage of process data for pulse plating processes and other conventional electroplating operations. VPC Software stands out for its simple handling and user friendly design.

Features:

- User friendly design to create and administrate pulse patterns

- Generation of clearly defined lists of patterns

- Creation and administration of complete process programs (Batch)

- Current density mode

- Effective current calculation (RMS)

- Ah metering

- Logging and documentation of process data