Titan metal Fabricators

TITAN Metal Fabricators designs and fabricates highly corrosion-resistant process equipment for any industry that has corrosion problems, including:

- Chemical

- Petrochemical

- Oil & Gas Liquefied Natural Gas (LNG)

- Pharmaceutical

- Steel Industry

- Energy

- Geothermal

- Biomass

- Nuclear Power

- Solar Power Facilities

- Metal Finishing, Plating & Anodizing

- Mining

- Water Desalination

Their primary business focus is on the manufacture of highly cost-effective process equipment such as Shell and Tube Heat Exchangers, Columns & Towers, Condensers, Reactors, Pressure Vessels, Piping, Piping Systems and Spargers. TITAN fabricators specialize in the reactive metals and corrosion-resistant alloys:

- Titanium

- Tantalum

- Zirconium

- Niobium

- Hastelloy®

- Monel®

- Inconel®

- High Nickel Alloys

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Lean Duplex Stainless Steel

Process equipment made from these materials can be used very effectively with extremely corrosive fluids and will last for decades if designed and fabricated correctly. TITAN fabricators have the knowledge and expertise to make sure all aspects of your project will come together – budget, design, fabrication and schedule – to yield the most trouble-free installation possible.

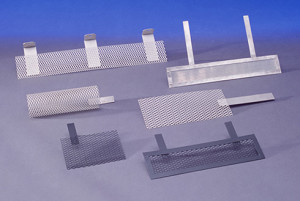

Titan anode baskets and hooks

TITAN anode baskets are built to the highest standards in the industry, and are backed by a five-year warranty on workmanship. As one of the largest stocking manufacturers of raw material, TITAN is pleased to provide customers with fast turnaround. If stock is not immediately available, TITAN will design, build and ship custom anode baskets in two weeks – wherever you need them.

Please contact us to learn more about the different sizes and styles of anode baskets and hooks that will be best for your application.

TITAN IMMERSION COILS

Through TITAN’s experienced technical support, its commitment to service and superior manufacturing quality, TITAN is dedicated to being the #1 supplier of corrosion-resistant equipment to the Metal Finishing, Plating and Anodizing Industries. TITAN supplies immersion coils in many different configurations to meet the specific needs of the industry. Grid coils are used to achieve the maximum heat transfer area in the least amount of dimensional space. Serpentine and “U” coils are used in situations were smaller heat transfer requirements are needed.

Available Materials of Construction:

- Titanium

- Stainless Steel

- Zirconium

- Tantalum

- Niobium

Standard Immersion Coil Options:

- Hanger Straps

- Anti-Flotation Arms

- Solution Level Jackets

- Horizontal or Vertical Orientation for Side Wall Mounting or Bottom Mounts Also Available

Standard Immersion Coil Features:

- 1″ O.D. Titanium Tubing

- Various Mounting Options Available

- Support Braces Between Riser Tubes for Coil Strength

- All Styles Equipped for Water or Steam Service

- Pressure tested at 100 PSIG

- 100% Inert Gas Purged Welds

- 5-Year Warrant

y

TITAN AUXILIARY ANODES

TITAN’s understanding of anode precision machining and manufacturing, electrochemistry and the processes requiring precious metal coatings, have served to bring TITAN to the industry forefront as one of the leading manufacturers of Auxiliary Anodes and Cathodes for many different applications-from automotive to circuit boards to wastewater.

Platinum-Clad Niobium or Titanium Auxiliary Anodes for Specialty Plating

The use of Platinum-clad and plated Titanium Auxiliary Anodes in hard chrome plating applications improve the anode dimensional, chemical and electrochemical stability over various operating conditions which improves the overall chrome deposit quality and consistency. These Auxiliary Anodes are cost-effective and cause no bath contamination by the Anodes.

Platinum and Mixed Metal Oxide Coated Titanium Anodes for Cathodic Protection

The use of Platinum and mixed metal oxide coated Titanium Anodes in precious metal plating applications offer exceptional electrical field characteristics and eliminate plating bath contamination as a result of anode disintegration. The increased plating speeds and homogeneous distribution of the electrodeposited layer makes these Anodes very inexpensive when compared with conventional type Anodes. The application of these Anodes is applicable to precious metal plating (gold, rhodium, platinum and palladium) as well as base metal plating (copper, nickel, hard chrome and decorative chrome).