FINISH THOMPSON INC.

(PLEASE CLICK ONE OF THE HEADINGS ABOVE TO JUMP DIRECTLY TO A SECTION)

Drum Pumps

PF SERIES HIGH PERFORMANCE DRUM PUMPS

The PF Series is a sealless high performance pump tube. It has a unique double suction impeller that provides high flow and high head. Featuring multiple material options and connections, the PF Series is designed for container to container transfer of acids, caustics, chemicals, and flammables.

Click image to see compatible motors and accessories.

Features:

- Polypropylene, PVDF, or 316SS tubes

- Interchangeable with motors

- Greater flow control with variable orifice discharge (PFM/PFP/PFV only)

- Up to 2000 cP

- FDA-compliant option

- Built-in hose and cord clips (PFM/PFP/PFV only

Applications:

- Acids

- Bases

- Solvents

- Water treatment chemicals

- Cleaners

- Plating solutions

- Kidney dialysis solutions

- DEF/AdBlue (diesel exhaust fluid)

EF SERIES ECONOMY DRUM PUMPS

The EF Series pumps provide an economical choice for light duty transfer. An ideal replacement for hand pumps.

Click image to see compatible motors and accessories.

FEATURES:

- Polypropylene, pure polypropylene/PVDF, or 316 stainless steel tubes

- Dual speed adjustable motors

- Tubes interchangeable with motors

- Lightweight & economical

- Integral strainer

- Plastic models have built-in hose cord & clips

APPLICATIONS:

- Light acids and bases

- Solvents

- Sodium hypochlorite

- Cleaners

- Coolants

- DEF/AdBlue (diesel exhaust fluid)

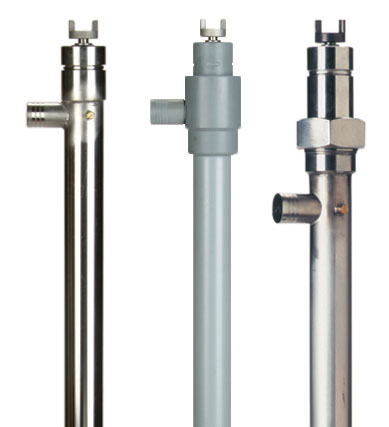

TT SERIES MID-PERFORMANCE DRUM PUMPS

TT Series pumps offer light to medium viscosity fluid handling. Drum pumps in this series are ideal for liquids containing small particulate or solvents.

Click image to see compatible motors and accessories.

fEATURES:

- 316 stainless steel or CPVC tube materials

- Tubes interchangeable with motors

- Up to 2000 cP with M6X air motor

- FDA-compliant STTS option

APPLICATIONS:

- Inks

- Paints

- Solvents

- Sodium hypochlorite

- Food & beverage

- Pharmaceutical

HVDP SERIES HIGH VISCOSITY DRUM PUMPS

This progressive cavity, positive displacement-style pump can handle viscous fluids up to 100,000 centipoise! The heavy duty HVDP offers multiple mechanical seal choices and matierals options for ultimate compatibility. Choose from the HR model (up to 20,000 cP) or the LR model (up to 100,000 cP).

Click image to see compatible motors and accessories.

features:

- Unique camlock feature for quick disassembly

- Optional foot design for drums with liners

- FDA-compliant options

- Bellows Type 21 mechanical seal

applications:

- Waxes

- Oils

- Resins

- Solvents

- Adhesives

- Silicone

- Lotions

- Honey

- Juice concentrate

- Hair & bath gel

- Corn syrup

BT SERIES HIGH VICOSITY DRUM PUMP

This stainless steel model with sealed design is made with PTFE screw-type lifting compressors to handle liquids with higher viscosities.

Click image to see compatible motors and accessories.

Features:

- Stainless steel tube construction

- Tube interchangeable with motors

- Up to 15,000 cP with 3 hp motor

Applications:

- Oils

- Resins

- Solvents

- Adhesives

- Polymers

- Gear lube

- Glycerin

SERIES TB MID-PERFORMANCE DRUM PUMPS

Lightweight pumps suitable for low to medium viscosity mild corrosives, solvents, and chemicals.

Click image to see compatible motors and accessories.

Features:

- Up to 200 cP

- Interchangeable with motors

- Pump tube designed to fit smaller bung openings

- Variable orifice discharge offers greater flow control

Applications:

- Light acids and bases

- Solvents

- bleach

- Swimming pool chemicals

SERIES TM DRUM MIXER

The TM Series Drum Mixer is a 4-blade, turbine drum mixer ideal for mild corrosives, solvents, or flammables of light to medium viscosity.

Click image to see compatible motors and accessories.

Features:

- Top-to-bottom mixing action

- Non-aerating, non-vortexing circulation

- Loosens and suspends bottom sediments

- Handles corrosive materials

- Pump tubes interchangeable with motor selections

- Up to 1000 cP with electric or air motor

Applications:

- Dyes

- Inks

- Paints

- Stains

- Mild corrosives

- Solvents & flammables

sealless magnetic driven pumps

DB SERIES PLASTIC MAGNETIC DRIVEN PUMPS

Designed from the ground up to be a chemical process pump, all bearing surfaces of the DB absorb any loads from hydraulic and other forces with a robust wall thickness on the suction end to ensure the integrity of the pump housing and allowing the user to directly attach to the pipe. From port design to bushings to o-rings, the DB series is available with a wide variety of optional components and materials to fit your application.

features:

• Close-coupled design

• Polypropylene or PVDF construction

• Neodymium magnets on every model

• Replaceable shaft and bushing

• ISO 1940 G2.5 balancing

• Mounts to NEMA and IEC motor frames

• Easy Set measurement-free outer drive

• Mounts to motor without disassembly

• Back pullout design

• Five-year warranty

applications:

• Chemical processes

• Metal plating/working

• Wastewater treatment

• Electronics manufacturing

• OEM equipment supply

• DI & High purity water

(Click The Images Below To Find Out More About A Specific Model)

SP SERIES SELF PRIMING MAGNETIC DRIVEN PUMPS

Combining deep lift capabilities and lightning fast priming with the advantages of mag-drive technology and corrosion resistant materials to handle the most difficult applications with no seal replacement, no leaks, and the capability to run dry without damage. The SP unique design creates a powerful deep vacuum in suction piping, allowing it to lift from as deep as 25 feet. The SP series uses only a fraction of the energy AODD pumps require. They are extremely efficient in their use of energy and they offer tremendous savings over other pump types.

Features:

• Polypropylene or PVDF construction

• Neodymium magnets on every model

• Replaceable shaft and bushing

• ISO 1940 G2.5 balancing

• Mounts to NEMA and IEC motor frames

• Easy Set measurement-free outer drive

• Mounts to motor without disassembly

• Back pullout design

• Five-year warranty

applications:

• Sumps

• Underground storage tanks

• Rail cars and tanker trucks

• Over-the-wall applications

• Double containment tanks

• Piping systems that tend to

have trapped or entrained air

(Click The Images Below To Find Out More About A Specific Model)

UC SERIES HEAVY DUTY MAG-DRIVE ANSI PUMPS

The UltraChem ANSI Dimensional is constructed from though ductile iron with Dupont Tefzel (ETFE) lining for superior corrosion resistance and the mag-drive pumps are engineered for the most demanding applications. Powerful neodymium magnets are used to drive the impeller through a carbon-filled ETFE-lined barrier for dependable, leak-free operation with no environmental emissions, no mechanical seal cost, and no seal support system. The UC Series carbon bushing option allows the pump to run dry for several minutes without damage. For greater chemical resistance with run dry ability, FTI also offers the diamond-like DRI-Coat silicon carbide bushing.

Features:

• Durable, corrosion-resistant Tefzel® lined ductile iron

casing

• Casing meets ANSI B73.1m & 73.3 for foot and flange

location

• Powerful neodymium magnets for dependable, leak-

free operation

• Modified concentric volute reduces radial thrust load

• Rear sealing ring to balance axial thrust

• Dual bushings provide optimum alignment

• Suction shaft support with integral straightening vanes

• Replaceable 2-piece impeller and drive hub

• Run dry capability with carbon or Dri-Coat SiC bushing

• Easy-set measurement free outer drive

• Exclusive vapor protection package to protect outer

magnetic drive and motor face from corrosive fumes

• Back pull-out design

• Casing drain standard

• Specific gravity over 1.8

Applications:

• Paper Mills

• Water treatment

• Plating & mental finishing

• Chemical manufacturing, blending, distribution

• Fume scrubbers

• Pharmaceuticals

• Truck loading/unloading

• Metals manufacturing

(Click The Images Below To Find Out More About A Specific Model)

sealed magnetic driven pumps

AC SERIES STAINLESS STEEL CENTRIFUGAL PUMPS

The AC Series metallic sealed centrifugal pumps are compact in design, 316 stainless steel constructed, and have a variety of seal combinations. The 316 stainless steel construction provides chemical resistance with superior flammable fluid handling capabilities. The AC Series is specifically constructed of FDA compliant materials which is ideal for food, beverage, pharmaceutical, and cosmetic applications where 3A is not required.

Features:

• Corrosion resistant 316 stainless steel

• Close coupled

• Back pull out design for easy service

• Compact design with secure V-clamp (304 stainless steel)

• NPT, BSP, tri-clamp, or flanged connections

• Standard, recessed, or high head impellers

• Bellows Type 21 seals (AC models only)

• Standard NEMA or IEC motor frames

• SS mounting plate for in-tank installation (AV models only)

• FKM, EPDM, or carbon lower bushings (AV models only)

• ATEX certified (AC models with ATEX motors only)

• FDA compliant materials (AC models with Buna elastomer

only)

• 1.8 specific gravity with no impeller trim

• Maximum temperature*: 300°F (149°C)

• Maximum working pressure: 100 psi (6.9 bar)

Applications:

• Chemical processing

• Printed circuit boards

• Pharmaceutical

• Waste water treatment

(Click The Images Below To Find Out More About A Specific Model)

GP SERIES PLASTIC CENTRIFUGAL PUMPS

The GP Series is a mechanically sealed plastic centrifugal pump which is reliable with corrosive chemical handling, has externally mounted seals, and non-metallic wetted components. The GP Series is an economical and value packed industrial pump providing reliable service in corrosive environments, suitable for a broad range of chemicals.

features:

• Mechanical seal horizontal centrifugal pump

• GF Polypropylene or CF PVDF construction

• NPT, BSP, or flanged connections

• Accepts standard NEMA or IEC motor frames

• Up to 7 1/2 Hp (3.0 kW) motors

• Back pull-out feature enables fast access for maintenance

• Close coupled or pedestal mounted

• Bellows, multi-spring or double seals

• Carbon, FKM or ceramic standard seal materials

• FKM or EPDM o-rings standard

• Over 1.8 specific gravity with no impeller trimming

applications:

• Chemical processing, spraying, transfer

• Plating recirculation/filtration, PCB etching/rinse

• Mild corrosive or low budget applications where

periodic seal replacement is not an issue

(Click The Images Below To Find Out More About A Specific Model)

vertical pumps

AK SERIES STAINLESS STEEL CANTILEVERED PUMPS

Rugged, metallic centrifugal pumps are compact in design, easy to operate and handle, and economically priced. Built from high quality 316 stainless steel, these pumps are available in horizontal, vertical, or vertical cantilevered designs. All wetted parts are constructed of corrosion resistant materials to withstand the harshest chemical environments.

features:

• Close coupled

• Back pull out design for easy service

• Compact design with secure V-clamp (304 stainless steel)

• NPT, BSP, tri-clamp, or flanged connections

• Standard, recessed, or high head impellers

• Bellows Type 21 seals (AC models only)

• Standard NEMA or IEC motor frames

• SS mounting plate for in-tank installation (AV models only)

• FKM, EPDM, or carbon lower bushings (AV models only)

• ATEX certified (AC models with ATEX motors only)

• FDA compliant materials (AC models with Buna elastomer

only)

• 1.8 specific gravity with no impeller trim

• Maximum temperature*: 300°F (149°C)

• Maximum working pressure: 100 psi (6.9 bar)

applications:

• Chemical processing

• Printed circuit boards

• Pharmaceutical

• Waste water treatment

(Click The Images Below To Find Out More About A Specific Model)

AV SERIES VERTICAL STAINLESS STEEL CENTRIFUGAL PUMPS

The AV Series Vertical Stainless Steel Centrifugal Pumps are compact in design, easy to operate and handle, and economically priced. They are designed with your application in mind. Fro greater application flexibility, AV pumps are offered in a variety of port sizes, sealed combinations, impeller types, and motor adapter sizes. Built from high quality 316 stainless steel, all wetted parts are constructed of corrosion resistant materials to with stand the harshest chemical environments.

features:

• Corrosion resistant 316 stainless steel

• Close coupled

• Back pull out design for easy service

• Compact design with secure V-clamp (304 stainless steel)

• NPT, BSP, tri-clamp, or flanged connections

• Standard, recessed, or high head impellers

• Bellows Type 21 seals (AC models only)

• Standard NEMA or IEC motor frames

• SS mounting plate for in-tank installation (AV models only)

• FKM, EPDM, or carbon lower bushings (AV models only)

• ATEX certified (AC models with ATEX motors only)

• FDA compliant materials (AC models with Buna elastomer

only)

• 1.8 specific gravity with no impeller trim

• Maximum temperature*: 300°F (149°C)

• Maximum working pressure: 100 psi (6.9 bar)

Applications:

• Chemical processing

• Printed circuit boards

• Pharmaceutical

• Waste water treatment

(Click The Images Below To Find Out More About A Specific Model)

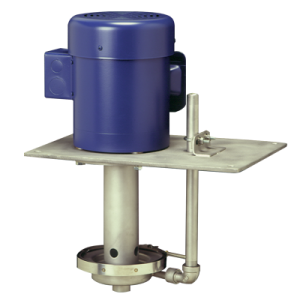

VKC SERIES PLASTIC VERTICAL MAG-DRIVE PUMP

The VKC Series Plastic Mag-Drive Pumps virtually eliminate aeration, foaming, and micro-bubbles. The productive design has molded components with o-ring protection to reduce maintenance by shielding liquid and fumes from the modular column and motor internals. VKC Series pumps can be mounted inside or outside the tank, for greater versatility. It is also offered as a multi staged sealless vertical mag-drive pump in the MSVKC Series, where it has a unique interconnecting drive shaft that transmits torque from magnetic coupling to the first stage impeller.

features:

• Non-aerating (no micro-bubbles)

• Reduced environmental emissions

• No wetted shaft bearings

• Mounts inside or outside of tank

• Polypropylene or PVDF construction

• Accepts standard NEMA or IEC motors

• Modular build: in 6” increments from 12” (30 cm)

to 60” (152 cm)

• Up to 1.8 specific gravity

• Maximum temperature 140oF (60oC)

• Maximum working pressure: 60 psi

applications:

• Circulation through filters & eductors

• Bio-filtration & odor control

• Fume scrubbers

• Chemical sumps

(Click The Images Below To Find Out More About A Specific Model)