poly products inc.

The initial use of the Poly Products Evaporative Tank was intended for the plating industry for dragout recovery of rinse water and ‘close the loop’ to a Zero Discharge Facility. Today, Creative minds have found many other ways to optimize production by using the ET-III-W evaporator including wastewater Minimization. The Poly Products evaporators are commonly used in a variety of industries including automotive, construction and sanitation, machine coolant, metal finishing, parts cleaning, DI regeneration waste, RO regeneration waste, Air Scrubber waste, air compressor condensate, ink and dyes, landfill runoff, or anything that is not allowed to go down the drain, and anywhere a bi-product is expensive to haul away. Because of environmental awareness and conservation, evaporators are now being more commonly used to close the loop and eliminate the drain.

evaporative tank

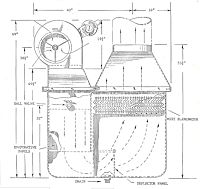

The Poly Products Evaporative Tank is available in two models, the ET-II-W and the ET-III-W. Each of these are ideally suited for dewatering spent solutions or wastewater that may have a high solids content. The evaporation mechanism eliminates any small, entrapping passages. Up down-draft spraying at very high flow rates produces high evaporation at moderate temperatures.

Those looking for thegreatest evaporation ratesat a given temperature will choose the Evaporative Tank-III-W for its high efficiency for any application.

A specialty use for the Evaporative Tank-III-W is the dewatering of decorative and hard chrome. The Evaporative Tank-III-W can be used directly on the plating tank to remove rinse spray water and fume scrubber water.

Dewatering of waste solutions (cutting oils, printing ink & paint washwater, spent chemical solutions, parts cleaning, DI & RO regeneration waste, air scrubber waste, air compressor condensation, ink and dyes) save the users of Evaporative Tank-III-W evaporators thousands of dollars in disposal costs. Where the need is for only 3 to 4 gallons of evaporation per hour, no added heat is required. Heat for evaporation is taken from the room.

applications

- Waste Water Treatment

- Industrial Evaporation

- Chemical Evaporation

- Oily Water Evaporation

- Plating

- Aggresive Solutions

condenser

The companion of the Poly Products Evaporator: the ET-Companion™ CONDENSER. The ET-III-W EVAPORATIVE TANK will evaporate water into the air stream that is passing though the unit and produce humid air, very much like a clothes-dryer at home. This humid air is then ducted out of the building, again just like the clothes-dryer at home. The air enters the evaporator and comes in direct contact with the solution droplets and absorbs water. The objective is to saturate the air, or make it 100% humid; the actual water content will vary based on the temperature of the air, thus the term “relative humidity”. The warmer the air, the more water it can hold. In round terms, for every 20°F the air temperature is increased, the water holding capacity of the air is doubled, or you could say that the relative humidity is cut in half. Heating the solution will in-turn heat the air and increase the evaporation rate. Now the 100% humid air exhausting from the ET-III-W EVAPORATIVE TANK can be ducted out of the building, as previously indicated, or it can be ducted into the inlet of the ET-Companion™ CONDENSER. The ET-Companion™ CONDENSER will cool the air, which will in turn reduce the amount of water the air can hold and condense the water out of the air stream. Inside the ET-Companion™ CONDENSER is a big specially made radiator, or Coil. This Coilis usually fed by a cooling tower or a chiller, or some other cold water source. As the warm humid air passes through the Coil, the air is cooled. Just as a cold drink appears to be sweating on a hot summer day, the Coil is dripping with condensate beads of distilled water. The beads of water drop down to the bottom of the Polyethylene tub of the ET-Companion™ CONDENSER. As the distilled water accumulates it will drain out of the 1” FNPT port in the bottom.

There are many benefits to the ET-Companion™ CONDENSER, but the three major benefits are as follows:

- Recovers all the water that is evaporated and returns it back to the end user for reuse in the form of distilled water.

- No more holes in your roof for exhaust ducting. No need for permits from the Air Quality People; this is a completely closed air system.

- Eliminates the need for air make-up in you building; no air is exhausted.

heated tank system

The Poly Products Evaporator System evaporates water from process solutions and waste waters under atmospheric conditions. The highest evaporation rate can be achieved by heating the solution prior to pumping it into the evaporator. This is accomplished by using our heated tank with either a gas-fired burner, steam coil or electric heater. The patented (#4790904) ET Evaporative Tank ™ is molded out of polyethylene, with no weld seams, for leak-free operation.

System Includes:

- Evaporative Tank ™

- Stainless steel heated tank and fire tube (carbon steel and polyethylene are also available)

- Gas fired burner, steam coil, or electric heater

- Control panel with temperature control, over temperature protection and level controls for automatic operation

- CPVC or stainless steel centrifugal pump to feed evaporator

- Skid mounting with piping and wiring installed at the factory

corro-line

The Poly Products Corro Product Line consists of the Corro-Fan and Corro-Ducts. Both provide excellent corrosion resistance. for a wide range of chemistries at temperatures ranging from zero to 200 degrees F.

Poly Products Corro-Fan

The Poly Products Corro-Fan is a premier in-line tube axial fan that is powder coated with a chemically robust two part Halar coating (ethylene chlorotrifluoroethylene). This coating provides corrosion resistance for a wide range of chemistries at temperatures ranging from 0 degrees F to 200 degrees F. The Corro-Fan has been used historically as simply the air mover of the Companion Condenser. However, it has recently found its place as a premier tube axial fan when corrosive air must be moved.

Poly Products Corro-Duct

These seamless ducts are leak-free and corrosion resistant. The design of our Corro-Duct in addition to the resistance polyethylene make this an ideal solution to even the most corrosive environments. Each Corro-Duct has a “slip fit” end so that it will easily slide into the adjacent mating Corro-Duct.