Serfilco MAGNETIC COUPLED PUMPS

MAGNETIC COUPLED PUMPS

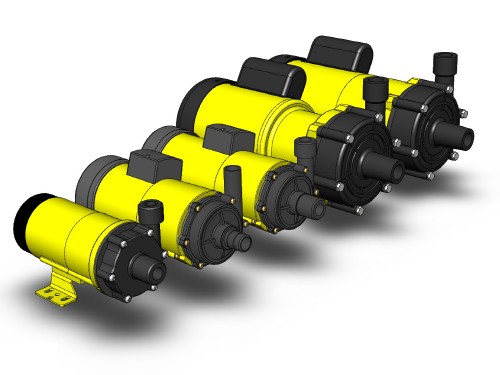

SERIES ‘A MAG’ MAGNETIC COUPLED PUMPS

Specifications

The Series ‘A’ magnetic coupled pumps are seal-less and leak proof, providing total solution and vapor containment. These pumps feature a shaft and bearing free design that allows them to be used for electroless solutions. The impeller magnet assembly floats in the radial magnetic field set up by the external drive magnet, eliminating the need for a shaft or spindle. The pump body can be rotated to selected direction of discharge. Neutralizing fluid will normally flush the interior adequately without need for disassembly. Impellers supplied on all standard seal-less pumps are suitable for water-like liquids up to 1.2 specific gravity.

Liquids with a higher specific gravity can be pumped if:

1. The outlet flow is restricted so the impeller magnet stays synchronized with the drive magnet.

2. The restrictions from a filter or other source of discharge head loss are sufficient to keep the impeller and drive magnets synchronized.

3. The overall diameter of the impeller is reduced

FEATURES:

• Flows to 9 gpm or 19 ft. TDH @ 60 Hz

• Non-metallic solution contact PP, CPVC, PVDF or ECTFE

• Continuous duty design

• Quiet, economical, centrifugal

• Low maintenance No spindles, bearings or thrust washers

mATERIAL:

PP, CPVC, PVDF, ECTFE

PERFORMANCE:

1-9 gpm

SERIES ‘B MAG’ MAGNETIC COUPLED PUMPS

Specifications

The Series ‘B Mag’ magnetic coupled pumps are sealless and leakproof, providing total solution and vapor containment. These pumps feature a shaft and bearing free design that allows them to be used for electroless solutions. The impeller magnet assembly floats in the radial magnetic field set up by the external drive magnet, eliminating the need for a shaft or spindle. The pump body can be rotated to selected direction of discharge. Neutralizing fluid will normally flush the interior adequately without need for disassembly. Impellers supplied on all standard seal-less pumps are suitable for water-like liquids up to 1.2 specific gravity.

Liquids with a higher specific gravity can be pumped if:

1. The outlet flow is restricted so the impeller magnet stays synchronized with the drive magnet.

2. The restrictions from a filter or other source of discharge head loss are sufficient to keep the impeller and drive magnets synchronized.

3. The overall diameter of the impeller is reduced

Features:

• Flows to 12 gpm or 24 ft. TDH @ 60 Hz

• Non-metallic solution contact PP, CPVC, PVDF or ECTFE

• Continuous duty design

• Quiet, economical, centrifugal

• Low maintenance No spindles, bearings or thrust washers

Material:

PP, CPVC, PVDF, ECTFE

Performance:

2-14 gpm

SERIES ‘X’ MAGNETIC COUPLED PUMPS

Specifications

SERIES ‘X’ Magnetic Coupled Pumps are the latest in magnetic coupled pump technology. Tested and proven design features provide a pump that is seal-less and leakproof. Available materials of construction and flow capacities from 1 to 25 gpm make these pumps an excellent choice for a wide variety of applications from water at ambient temperatures to harsh chemicals at elevated temperatures. Standard ‘X’ models have strong magnets and powerful, highly efficient continuous duty motors which allow them to operate non-overloading and provide continuous flow with liquids up to 1.3 specific gravity. Compact and quiet Series ‘X’ pumps are designed to provide years of trouble-free operation. The following information covers standard Series ‘X’ models.

Features:

• Flows from 1 to 25 gpm @ 60 Hz (3 – 78 LPM @ 50 Hz)

• Non-metallic solution contact PP, PVDF, ETFE, FKM

• NPT or hose barb connections

• Strong magnets will handle liquids to 1.3 specific gravity

• Continuous duty design

• Compact, quiet and efficient

• UL recognized, Œ conforming

• Motors are available 100-110V/1/50-60 Hz or 230V/1/50-60 Hz

• Designed to replace similar OEM pumps

Material:

PP, PVDF

Performance:

1-25 gpm

SERIES ‘M’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘M’ Magnetic-Coupled Pumps are seal-less and “leak-proof”, providing total solution and vapor containment. They are available in two different materials of construction for a wide range of chemical and temperature compatibility. The relationship of the impeller magnet to the liner reflects an advanced design which allows extended operation at dry run or during loss of prime without causing damage to the pump. The impeller head is separate from the impeller magnet hub for field interchangeability. The mouth ring design eliminates the need for a front thrust washer. By using rare-earth magnets, this pump provides flow and pressure equal to that of a physically much larger pump. This powerful coupling allows the pump to operate at full flow with the full size impeller while handling liquids up to 1.6 S.G. @ 30 CPS.

features:

• Flows to 70 gpm or 56 ft. TDH @ 60 Hz (220 LPM or 12m @ 50 Hz)

• Non-metallic solution contact Glass reinforced PP or carbon reinforced PVDF

• Extended dry run Unique design helps prevent pump damage

• Powerful rare-earth magnets Provide sure coupling to 1.6 S.G. @ 30 CPS

• Connections NPT or BSP Optional: 1/4″ NPT drain

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

10-70 gpm

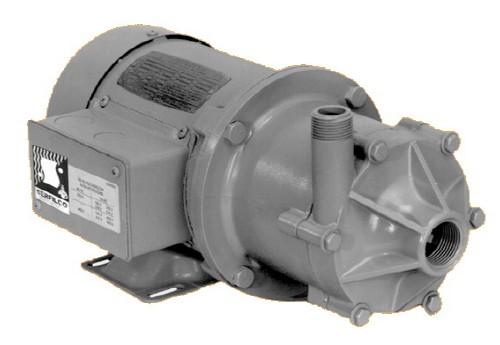

SERIES ‘D’ MAGNETIC COUPLED PUMPS

Specifications

SERIES ‘D’ Magnetic Coupled Pumps are seal-less, providing for maintenance-free and “leak-proof” operation. The magnetic coupling acts as a clutch to provide overload protection. The broad range of construction materials allows for a variety of applications and service with most corrosive solutions. The impeller magnet assembly floats in the radial magnetic field set up by the motor driven external drive magnet. The impeller is designed to deliver the maximum flow and pressure utilizing the available strength of the synchronized magnets. The standard diameter impeller is suitable for waterlike liquids to 1.1 specific gravity. Liquids having a higher specific gravity can be pumped if the overall diameter of the impeller is reduced, the outlet flow is restricted,or the restrictions from a filter or other head loss is sufficient to keep the impeller magnet in synchronization.

Features:

SEAL-LESS and LEAK-PROOF for total solution containment reliable, trouble-free pumping

• Corrosion resistant PP, PVDF, PPS SS316

• Centrifugal – quiet, vibration-free

• Flows to 53 gpm or 58 FT. TDH @ 60 Hz

• Maximum liquid temperature

PP and PPS: 150°F

PVDF: 220°F, SS316 : 250°F

material:

PP, PVDF

Performance:

5-45 gpm

SERIES ‘ME’ MAGNETIC COUPLED PUMPS

Specifications

Standard models are constructed of glass-fiber reinforced polypropylene or carbon-fiber reinforced PVDF for suction casing, magnet liner and impeller. Impeller magnets are encapsulated in unfilled polypropylene or unfilled PVDF. The front and rear thrust rings and shaft are high purity, fluoride resistance alumina ceramic.

The impeller thrust ring is molybdenum disulfide filled PTFE. The casing ‘O’-ring is Viton. Maximum pump pressure; 80 PSI (5.4 bar). Motors are continuous-duty and have a 1.15 service factor. Single phase motors are supplied with 8ft (2.4m) of 3-wire cord and plug.

Features:

• Flows to 95 GPM or 54 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Glass reinforced polypropylene or carbon reinforced PVDF

• High operating efficiency up to 70%

• Capable of running dry without damage

• Powerful rare earth magnets

• Choice of connections: NPT or BSP threads, flanges or unions.

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

95 gpm

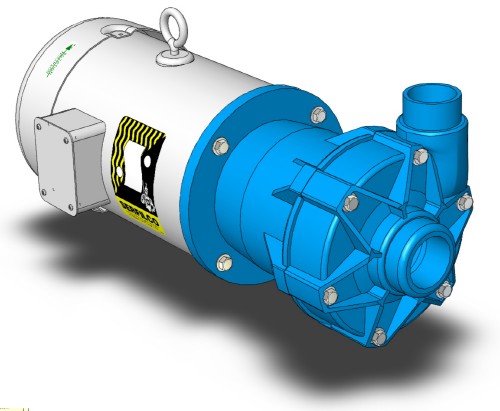

SERIES ‘MES’ MAGNETIC COUPLED PUMPS

Specifications

Standard models are constructed of glass-fiber reinforced polypropylene or carbon-fiber reinforced PVDF for suction casing, magnet liner and impeller. Impeller magnets are encapsulated in unfilled polypropylene or unfilled PVDF. The front and rear thrust rings and shaft are high purity, fluoride resistance alumina ceramic.

The impeller thrust ring is molybdenum disulfide filled PTFE. The casing ‘O’-ring is FKM. Maximum pump pressure; 80 PSI (5.5 bar). Motors are continuous-duty and have a 1.5 service factor.

Features:

• Flows to 54 GPM or 63 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Polypropylene or Carbon reinforced PVDF

• Deep-lift capacity Up to 25 feet / 7.6 meters

• Fast priming 18 feet / 4.6 meters in 90 sec.

• Extended dry run capability

• Powerful rare earth magnets

• Accepts standard motors

Material:

PP, PVDF

Performance:

54 gpm

SERIES ‘F’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘F’ Magnetic-Coupled Pumps are seal-less and “leak-proof” providing total solution containment. Available in two different materials of construction for a wide range of chemical and temperature compatibility. By using powerful rare-earth magnets, this pump provides flow and pressure equal to that of a physically much larger pump. This powerful coupling allows the pump to operate with the full size impeller at full flow while handling liquids up to 1.8 S.G. or 50 CPS. These powerful magnets create a balancing field which eliminates loading on bearing surfaces, thus providing an extended life span of the bushing compared to that of many standard magnetic coupled pumps. This same “balancing” gives the pump its ability to run dry for 10 minutes, or 30 minutes if wetted, before damage occurs. A fluted bushing provides positive internal liquid circulation/flush along the shaft spindle. These pumps utilize a high-purity ceramic stub-shaft which eliminates breakage. A unique feature of this pump is its ability to mount to NEMA and metric frame motors, thus giving motor options of TEFC, EXP, chemical duty and 575V. The pump is also available longcoupled.

Features:

• Flows to 255 gpm or 135 ft. TDH @ 60 Hz (804 LPM or 28.6m @ 50 Hz)

• Non-metallic solution contact Glass reinforced PP or Carbon reinforced PVDF

• Can run dry for 10 minutes, or 30 minutes if wetted, without causing pump damage

• Powerful rare earth magnets Provide sure coupling to 1.8 S.G.

• Accepts standard motors NEMA or IEC metric (except 143/145 frame)

Material:

PP, PVDF

Performance:

25-200 gpm

SERIES ‘FE’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘FE’ magnetic coupled pumps are seal-less and “leak-proof”, providing total solution containment. They are available in a choice of two different corrosion resistant materials for a wide range of chemical and temperature compatibility and are ideal for handling even the most difficult applications. The Series ‘FE’ magnetic coupled pumps offer extremely high operating efficiencies for their size; up to 70%. This technological advancement results in smaller motor horsepower and means lower energy consumption and operating costs over the long life cycle of the pump. These pumps utilize powerful rare earth magnets which allow them to operate at full flow with a full size impeller while handling liquids over 1.8 specific gravity. Additionally the Series ‘FE’ is capable of running dry without damage when equipped with the standard carbon bushing and under optimum operating conditions. This helps protect the pump from operator errors and system upsets

Features:

• Flows to 130 gpm or 97 ft. TDH @ 60 Hz

• Non-metallic solution contact

• High operating efficiency – up to 70%

• Capable of running dry without damage

• Powerful rare earth magnets Provide sure coupling

• Choice of connections – NPT, BSP, flanges or unions

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

15-130 gpm

SERIES ‘FES’ SELF PRIMING MAGNETIC COUPLED PUMPS

Specifications

Series ‘FES’ self-priming magnetic coupled pumps are seal-less and “leak-proof” providing total solution containment. They are available in a choice of two different corrosion resistant materials for a wide range of chemical and temperature compatibility and are ideal for handling even the most difficult applications. The outstanding self-priming feature of the Series ‘FES’ combines deep-lift capabilities (up to 25 feet) and lightning-fast priming (18 feet in 90 seconds). The priming chamber’s gooseneck design eliminates the need for internal check valves while ensuring that enough liquid is retained for efficient re-priming. These pumps utilize powerful rare earth magnets which allow them to operate at full flow with a full size impeller while handling liquids over 1.8 specific gravity. Additionally the Series ‘FES’ is capable of running dry without damage when equipped with the standard carbon bushing and under optimum operating conditions. Their innovative and highly efficient design, and low energy consumption make these pumps one of the most versatile and economical centrifugal pumps on the market.

Features:

• Flows to 120 gpm or 90 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Deep-lift capability up to 25 feet

• Fast priming 18 feet in 90 sec.

• Capable of running dry without damage

• Powerful rare earth magnets Provide sure coupling

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

performance:

10-120 gpm

SERIES ‘TM’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

The Series ‘TM’ magnetic coupled centrifugal pump directly addresses the weaknesses of other magnetic drive pumps. From high torque compact magnets to a large diameter reduced length shaft to massive precision finished thrust bearings, the ‘TM’ pump is designed to excel where other pumps fail. Heavy walled voluted casings improve pump strength, internal shaft support, chemical resistance, pressure and temperature capabilities as well as hydraulic efficiencies. Standard models are non-overloading with stated elevated specific gravity liquids

Features:

• Flows to 130 gpm or 68 ft. TDH @ 60 Hz (409 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PP or PVDF pump Choice of EPDM or FKM elastomers

• High torque magnets To 1.5 S.G. with standard models

• Massive thrust bearings

• Heavy walled voluted casings for higher temperature applications

• Centrifugal, quiet, vibration-free

• Seal-less, leak-free magnetic coupled

• For use with standard NEMA or IEC ‘C’-face motors

Material:

PP, PVDF

Performance:

20-140 gpm

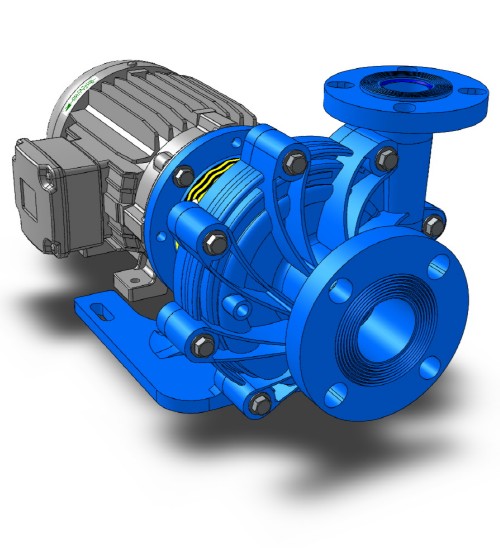

SERIES ‘UC’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

Series ‘UC’ magnetic coupled pumps are seal-less, ANSI dimensional, ETFE lined pumps that are specifically designed for corrosive chemical applications in a wide range of industrial services. The Series ‘UC’ pump is engineered to provide the utmost in reliability and longer pump life in even the most extreme applications. All wetted surfaces are non-metallic to provide superior chemical resistance. The Series ‘UC’ pump has a tough ductile iron casing bonded with a pure Tefzel (ETFE) lining. The enclosed impeller and pump liner are precision molded from carbon fiber reinforced ETFE while the pump liner also has an external containment shell of glass reinforced vinyl ester for optimum pressure resistance. The dual impeller bushings, shaft and front and rear thrust rings are sintered silicon carbide. The impeller thrust ring is manufactured from Fluorosint. These components provide exceptional chemical resistance and wear characteristics at all flows.

fEATURES:

• Flows to 330 gpm or 320 ft. TDH @ 60 Hz

• Non-metallic solution contact ETFE

• Up to 250°F applications

• ANSI dimensional

• Powerful rare earth magnets

• Magnetic coupled for leak-free pumping

• Accepts standard motors NEMA or IEC metric

Material:

ETFE lined

Performance:

25-330 gpm

SERIES ‘Z’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

Series ‘Z’ Magnetic Coupled Pumps are the latest in magnetic coupled pump technology. Tested and proven design features provide a pump that is sealless and leakproof. Available materials of construction and flow capacity to 145 gpm make this pump an excellent choice for a wide variety of applications. Standard ‘Z’ models have strong magnets, allowing them to provide continuous flow with liquids up to 1.1 specific gravity. Trimmed impellers allow continuous flow with liquids to 1.9 specific gravity. Durable and corrosion resistant construction of PP or ETFE ensures efficient and reliable performance for even the most critical applications. Standard TEFC motors, strong magnets and highly efficient impellers provide a quiet and efficient pump designed for years of trouble-free operation.

fEATURES:

• Flows to 145 gpm @ 60 Hz (548 LPM @ 50 Hz)

• Non-metallic solution contact PP / FKM or ETFE / FKM

• Powerful magnets

• Seal-less pump provides zero leakage and low friction for energy efficiency

• High efficiency closed impellers

Material:

PP, PVDF

Performance:

20-140 gpm