carlson Erie corporation

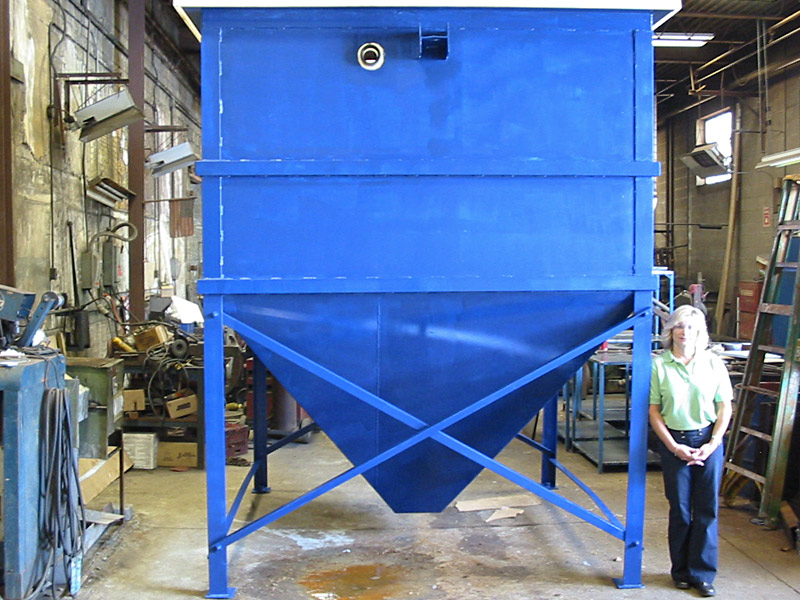

Carlson Erie produces a wide range of items needed for the manufacturing industry – no project is too large or too small. Tanks and ventilation systems of any size or shape can be custom designed to fit even in the most space-restricted areas. They are also able to repair, refurbish and/or modify your existing tanks, racks and exhaust systems to accommodate your new upgrades.

Plastic and metal tanks

Carlson Erie has sixty years of experience in designing, fabricating and installing a variety of different styles of tanks. With both metal and plastic fabricating departments, they have the flexibility to manufacture tanks from an extensive range of materials. Polypropylene tanks, carbon steel tanks and stainless steel tanks are the most common, but many other tank materials are available. The plastic tanks offered by Carlson Erie are manufactured by qualified plastic fabricators. The metal tanks are also manufactured by qualified metal fabricators to ensure the best equipment quality and performance. With in-house machining, assembly, electrical equipment, piping, sandblasting, polishing, painting and CNC routing capabilities, they can ensure to help minimize the cost of fabrication. In addition to fabricating new tanks, Carlson Erie will repair and modify existing tanks.

Types of Tanks include:

- Anodizing Tanks

- ASME Code Tanks

- Black Oxide Tanks

- Chemical Tanks

- Chromating Tanks

- Cleaning Tanks

- Corrosion Resistant Tanks

- Double Wall Tanks

- Electrocoating Tanks

- Etching Tanks

- Non-Code Tanks

- Phosphating Tanks

- Pickling Tanks

- Plating Tanks

- Secondary Containment Tanks

- Storage Tanks

- Waste Treatment Tanks

- Wire Processing Tanks

add-on options include:

- Bussing

- Saddles

- Mixer Bridges

- Flexible or Rigid Liners

- Pumps & Filters

- Spray Headers

- Air Spargers

- Covers

- Blending Baffles

- Heaters & Controllers

- Skimming Weirs

- Other Custom Features

racks and baskets

Carlson Erie has extensive knowledge of plating environments which enables them to offer rack designs that optimize production, coating thickness and durability. They create custom racks and fixtures of any size or shape for both automatic and hand-line production facilities. From in-house plastisol coating to chemical stripping services, they can provide the best rack and basket production that you can count on.

Racks and baskets are designed and fabricated for:

- Anodizing

- Cleaning

- Electropolishing

- Etching

- Painting

- Plating

- Powder Coating

- Printed Circuit Boards

Exhaust and duct work

Carlson Erie offers exhaust systems that feature top-of-the-line fans, blowers and fume scrubbers. By carefully selecting the highest quality components in the industry while also providing custom engineered systems, they ensure that the equipment will involve minimal maintenance and perform effectively. Carlson Erie has plastic fabricators that offer quality construction for all of your ventilation components. They provide complete installation services to ensure that your system operates according to your specifications.

They offer the following exhaust and duct work options.

Hoods:

- Manufactured from thermoplastics, plastisol-coated steel or stainless steel.

- Custom size, shape and material thickness to meet your specific requirements.

Stack Caps:

- Prevent rain or snow from entering the fan housing during operation.

- Stop cold air entry in idle systems.

Ducting:

- Fabricated from thermoplastics, or stainless steel

- Meets SMACNA and/or National Voluntary Products Standards PS 15-69

- Factory Mutual Approved PVC exhaust duct

Blowers and Fans:

- Ranging in size from 400 CFM to 150,000 CFM

Fume Scrubbers:

- Ranging in capacity from 500 CFM to 100,000 CFM