Ceco-mefiag filter systems

Polypropylene Disc Filter System

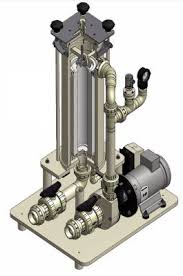

POLYPROPYLENE ELECTROPLATING FILTER SYSTEMS – 0310/0620/0640 PP SERIES

The smallest CECO Mefiag brand Polypropylene Electroplating Filter Systems feature horizontal disc technology and capacities from 600 to 1,600 gph

Features:

- Designed for the filtration of nickel, copper and zinc electrolytes

- Operating temperature to 180°F

- For plating tanks from 200 to approximately 400 gallons depending on the type of process

- Can be supplied with horizontal discs or cartridges depending on the application

Benefits:

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

POLYPROPYLENE ELECTROPLATING FILTER SYSTEMS – 2500/3500/4500 PP SERIES

The CECO Mefiag brand mid-range Polypropylene Electroplating Filter Systems units feature horizontal disc technology and capacities from 2,500 to 7,500 gph.

Features:

- Designed for the filtration of nickel, copper and zinc electrolytes

- Operating temperature to 180°F

- For plating tanks from 400 to approximately 1,000 gallons depending on the type of process

- Can be supplied with horizontal discs or cartridges depending on the application

Benefits:

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

pleated polypropylene Cartridge systems

MKF SERIES-PLEATED POLYPROPYLENE FILTER SYSTEMS

The CECO Mefiag brand solid Pleated Polypropylene Filter combines high volume filtration with high performance pleated element for greater dirt holding capacity.

Features:

- Single 6″ O.D. cartridge for ease of change out

- Solid polypropylene construction

- 27 sq ft of surface area

Benefits:

- Low Total Cost of Ownership

- Designed for high flows (4600 gph) with small footprint

High-Capacity Disc Filter Systems

LS SERIES-HIGH CAPACITY ELECTROPLATING FILTER SYSTEMS

LS Series – High Capacity Electroplating Filter Systems: 3200/6500 – Single Chamber; 13000 – Dual Chamber. The CECO Mefiag brand steel rubber-lined High Capacity Electroplating Filter Systemsfeature horizontal disc technology and capacities of 3,200 to 6,500 gph for Single Chamber and up to 13,000 gph for Dual Chamber.

Features:

- Designed for the filtration of nickel, copper and zinc electrolytes

- Operating temperature to 180°F

- Depending on the type of process, single chamber systems are designed for plating tanks ranging from 600 to 1,500 gallons; dual chamber systems are designed for plating tanks up to 3,000 gallons

- Can be supplied with high profile (for zinc) or low profile (for nickel and copper) horizontal discs

- Special X-versions of these units are available for filtration of aggressive liquids such as acid copper, acid zinc or acid tin. The slurry tank and filter housing on X-versions are lined inside and out with ebonite, and the pump shaft is titanium

Benefits:

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

- Mechanical lifting device for easy access to filter pack

HF SERIES-HIGH CAPACITY ELECTROPLATING FILTER SYSTEMS

HF Series – High Capacity Electroplating Filter Systems: 4500/9000/15000 – Single Chamber ; 18000/30000 – Dual Chamber. The CECO Mefiag brand steel rubber-lined High Capacity Electroplating Filter Systemsfeature horizontal disc technology and capacities of 4,500 to 15,000 gph for Single Chamber and capacities from 18,000 to 30,000 gph for Dual Chamber.

Features:

- Designed for the filtration of nickel, copper and zinc electrolytes

- Operating temperature to 180°F

- Capacities range from 4,500 to 15,000 gph

- Depending on the type of process, single chamber systems are designed for plating tanks ranging from 1,000 to 4,000 gallons; dual chamber systems are designed for plating tanks from 4,000 to 6,000 gallons

- Can be supplied with high profile (for zinc) or low profile (for nickel and copper) horizontal discs

- Special X-versions of these units are available for filtration of aggressive liquids such as acid copper, acid zinc or acid tin. The slurry tank and filter housing on X-versions are lined inside and out with ebonite, and the pump shaft is titanium

Benefits:

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

- Mechanical lifting device for easy access to filter pack

Oil Absorbing Filter Systems

V SERIES-OIL ABSORBING FILTER SYSTEMS

The CECO Mefiag brand V Series – Oil Absorbing Filter Systems are specifically designed for the removal of oil and grease from cleaning solutions, rinse water, wastewater and other corrosive liquids.

Features:

- Operating temperatures to 180°F

- Specially designed for the filtration of degreasing baths

- Equipped with a specially designed perforated basket for an optimal contact between the oil absorbing filter material and the liquid

- Can be equipped with a polypropylene slurry tank

- Filter basket has a capacity of 3, 5, 9, or 16 gallons depending on the model

Benefits:

- Low Total Cost of Ownership

- Hydrophobic meltdown polypropylene media provides best oil absorbing characteristics as well as large surface area

- The absorption capacity of the oil adsorbing filter material is 1:8-12. (This means that 1 lb. of oil adsorbing filter material can absorb 8 to 12 lbs. of grease and dirt resulting in much longer lifetime of your degreasing baths)

CR SERIES-CHROMIC ACID DISC FILTER SYSTEMS

CR SERIES-CHROMIC ACID DISC FILTER SYSTEM

The CECO Mefiag brand CR Series – Chromic Acid Disc Filter Systems are special filtration units of polyvinylidene difluoride (PVDF) lined or solid PVDF construction. These units, which feature horizontal disc technology and capacities from 800 to 6,500 gph, are specifically for use in processes where chromic acid is involved (hard chromium, etching, etc.)

Features:

- Designed for the filtration of chromic acid solutions including etching of ABS

- Operating temperatures to 180°F

- For plating tanks from 400 to approximately 3,300 gallons

- Can be supplied with horizontal discs or cartridges depending on the application

Benefits:

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

- Mechanical lifting device for easy access to filter pack

HT SERIES-HIGH TEMPERATURE DISC FILTER SYSTEMS

HT SERIES-HIGH TEMPERATURE DISC FILTER SYSTEMS

The CECO Mefiag brand HT Series – High Temperature Disc Filter Systems are specifically designed for handling high temperature solutions such as hot-sealing baths, electroless nickel and hot soak cleaners.

Features:

- Operating temperatures to 210°F

- Precoated flow rate to 10,000 GPH

Benefits:

- Low Total Cost of Ownership

- Unique insulated double-wall filter chamber

- Stainless steel construction

- Diaphragm pressure gauge for high temperature service

- Horizontal disc technology for greater surface area and maximum efficiency

- Mechanical lifting device for easy access to filter pack