hardwood line manufacturing

For over 85 years Hardwood Line Manufacturing has been supplying metal finishing equipment designed and adapted for the specific needs of customers. They offer a full line of reliable equipment, engineered to deliver optimal quality and productivity. Before and after the sale we provide full support, assisting you with system design, training, installation, and technical support.

plating Barrels

cylinder construction

Cylinders can be constructed in your choice of either Fusion Welded, Dovetail Fusion, or Dovetail Screw. Exterior machined pockets produce a structural rib work that adds strength. The pockets also reduce wall thickness thereby enhancing solution transfer and enabling a more efficient current distribution. Interior “channels” funnel solution to the perforations increasing drainability, preventing peening, and eliminating adhesion.

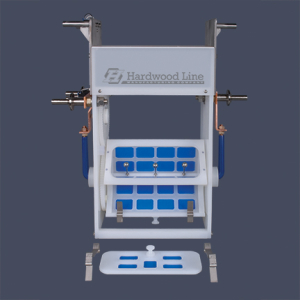

superstructure configurations

Hardwood Line offers 4 basic superstructure configurations:

- Overhead Motor Control (OMC) (shown)

- Gear Drive Side Drive (GDSD)

- Belt Driven Side Drive (BDSD)

- Automatic Side Drive (ASD)

portable barrels

Our portable barrels are available in three adaptable basic models and can be fitted with any cylinder style (standard hex, PaddleWheel, SprayThru™).

Portables are available in the following sizes: 4×6, 5×6, 6×12, 8×12, 8×18, 10×18, 10×24, 12×24.

cylinder styles

- Standard

- HexPaddleWheel™

- SprayThru™

- LaserPerf™

specialty barrels

- Oscillating Plating Barrel

- HOB Barrel

- Captured Parts Processing System

tanks

poly construction methods

All Hardwood Line tanks, constructed of 1” or thicker poly walls, are fusion welded. Tanks with wall thicknesses less than 1” are constructed of a single heat formed piece. Both methods ensure maximum strength at all stress points.

tank construction materials

Hardwood Line offers tanks in 5 Standard materials:

• Polypropylene

• Steel

• Stainless Steel

• Fiberglass

• Lined Steel

Other materials such as PVC, CPVC, and KYNAR are available upon request.

tank options

- Motor Platforms

- Sump Sections

- Partitions

- Dams

- Compartmentalization

- Top Flanges

tank reinforcement

- Steel Skeleton

- Encapsulated Steel Girth

- External Poly Ribs

tank accessories

- Plumbing

- Saddles

- Bussing

- Electric Heaters

- Plate Coils

- Recirculation Systems

- Air Spargers

- Dummy Anodes

- Filters

- Agitation

- Digital Connections

rinising systems

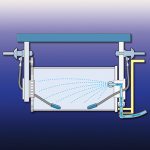

SprayThru™ Rinsing Systems

SprayThru™ rinsing systems combine improved rinsing with water conservation and pollution control. Because these systems employ only a single rinse station, valuable floor space is freed up for additional production stations.

RinseMaster® 5 and the OneShot™

Hardwood Line offers two SprayThru rinsing systems to suit your requirements:The RinseMaster® 5 and the OneShot™. These systems all utilize the same SprayThru™ barrel and tank. The SprayThru™ barrel can also be used throughout your line to further increase production.

rack rinsing

The RinseMaster Spray Rinsing system can also be utilized on a Rack System. The Rack Rinse tank is specifically designed for this use.