Serfilco BAG FILTER CHAMBERS

Bag Filter Chambers

SERIES ‘L’ BAG FILTER CHAMBERS

Specifications

The Series 410 – 430 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers provide surface area of 0.75 to 2.25 sq. ft. and are designed for small tanks or small filtration applications. The 410 – 430 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The design is based on our proven ‘L’ chamber with molded base and cover and clamp closure. Depending on the application and the solution being filtered, these chambers are capable of handling 100 PSI pressure at ambient conditions and 200 F at lower pressures. Because of their size, these chambers can provide a more economical solution for smaller filtration applications.

Features:

• Non-metallic solution contact PVC, CPVC, PP or PVDF construction EPDM elastomers standard (FKM optional)

• Sizes to 2.25 square feet (0.23 sq/m) For flow rates to 20 GPM (75 LPM)

• Top inlet – bottom outlet design

• Easy to service Clamp ring cover closure – No tools required

• Port size 3/4″ hose quick-connect coupling x 3/4FNPT

• PP filter bags 1, 5, 10, 25, 50 and 100 micron

Material:

PVC, CPVC, PVDF

Performance:

20 gpm

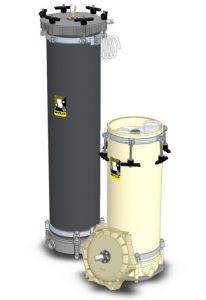

SERIES ‘S’ BAG FILTER CHAMBERS

Specifications

The Series 630 and 640 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers have been redesigned to make them easier to operate and more convenient to service. The new design features a bottom inlet and bottom outlet which allows these chambers to be hard piped and allows the user to change bags without disconnecting any hoses or piping. Additionally the new employs easy to service swing bolt cover closure.

As before the Series 630 and 640 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The single bag design provides filter area to 5.0 sq. ft. and micron retention Ratings of 1 to 100.

fEATURES:

• Non-metallic solution contact

• Bottom inlet and outlet design

• Easy to service Swing bolt cover closure

• Port sizes 1 FNPT

• PP filter bags

mATERIAL:

PVC, PP, CPVC, PVDF

pERFORMANCE:

3.5 – 5 sq. ft., 40 gpm

SERIES ‘G’ BAG FILTER CHAMBERS

Specifications

The Series 1235 and 1255 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers have been redesigned to make them easier to operate and more convenient to service. The new design features a bottom inlet and bottom outlet, which allows these chambers to be hard, piped and allows the user to change bags without disconnecting any hoses or piping. Additionally the new design utilizes multiple 4″ flanged bags which provides greater surface area for the same size chamber. As before the Series 1235 and 1255 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The new design provides filter area to 19.5 sq. ft. and micron retention ratings of 1 to 100.

Feratures:

• Non-metallic solution contact

• Bottom Inlet / outlet design

• Easy to service

• Port size 1 1/2″ NPT

Material:

CPVC, PVC, PP

Performance:

12-19.5 sq ft, 80-100 gpm

STEEL AND STAINLESS STEEL BAG FILTER CHAMBERS

Specifications

Single Bag Chambers Housing lid has a 3-bolt swing closure with a vent port. Connections are as noted with standard side inlet and bottom outlet. Housing is supplied with two differential pressure ports to measure the differential pressure across the filter bag. A two-part epoxy finish is applied on the carbon steel vessels to maximize the life of the housing; stainless steel vessels are supplied with a satin finish. Basket material is constructed of 316 stainless steel with 9/64″ perforations to act as a strainer or to accept a liquid filter bag. Basket for KBS6 and KBS8 chamber seats onto an “O”-ring in the basket support.

Features:

• Carbon steel or stainless steel construction

• EPDM elastomers standard (FKM optional)

• Swing bolt cover closure with eye nuts

• 316 SS strainer basket

• Differential, drain and vent ports

• 2-part epoxy paint on carbon steel

Material:

ST, SS

Performance:

Click image for this information