Serfilco Cartridge Filter Chambers

CARTRIDGE FILTER CHAMBERS

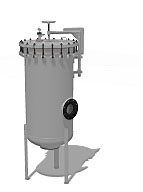

SERIES ‘K’ CARTRIDGE FILTER CHAMBERS

Specifications

The Series ‘K’ Metal Filter Chambers provide excellent value and are available in either a cartridge or bag design and with a choice of carbon steel, 304 or 316 stainless steel construction. Cartridge chambers range in size from a single 10″ cartridge to 448-10″ cartridge capacity. Bag chambers are from 0.5 sq. ft. to 26.4 sq. ft. of surface area. These chambers are ideal for either re-circulatory or single pass filtration in either series or parallel flow configurations. The wide range of sizes, styles and options means that due to chemical compatibility or temperature considerations require a metal filter chamber.

Features:

• Carbon steel or stainless steel construction

• EPDM elastomers standard (Viton® optional)

• Swing bolt cover closure with eye nuts

• 300 PSI pressure rating (single) 150 PSI pressure rating (3-round and 6-round)

• 316 SS internals

• Differential, drain, and vent ports

• Adjustable support legs

• 2-part epoxy finish on carbon steel

Material:

SS ST

Performance:

Very’s depending on unit. Click image for more information.

SERIES ‘L’ PLASTIC FILTER CHAMBER

Specifications

Flow rates up to 34 gpm depending upon style and length of filter cartridge, solids content, viscosity, pressure drop, size of connection and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered.

Features:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings to 160 psi

• Clamp ring closure or optional external tie rod

• Variety of sizes

• Port sizes 3/4″ and 1″ NPT

• O-ring seal at cover & vent valve

• Easy servicing, no tools required

Material:

CPVC, PVC, PP, PVDF

Performance:

1-40 gpm

SERIES ‘S’ PLASTIC FILTER CHAMBER

Specifications

These filter chambers are designed for filtering process solutions where clarification will extend operating life and improve quality.

• Depth wound, pleated, carbon or membrane cartridges

• Positive cartridge seal for: DOE (optional – SOE for 222 O-Ring)

• Cleanable sleeves (used with or without precoat) Flow rates up to 68 gpm depending upon style and length of filter cartridge, solids content, viscosity, pressure drop, size of connection and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered.

fEATURES:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings up to 135 psi

• 0-60 psi pressure gauge, mounted on a gauge guard

• Integral shell-base assembly

• Inlet to outlet at 90° or 180° aspect

• Variety of sizes are available From 3 to 15 of 10″ cartridges

• Port sizes 1NPT

Material:

PVC, CPVC, PP, PVDF

Performance:

3-75 gpm

SERIES ‘G’ PLASTIC FILTER CHAMBERS

Specifications

Flow rates to 125 gpm depending upon size of chamber, style of filter cartridge, solids content, viscosity, pressure drop and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered. All chambers have cover swing bolts with tee handles, SS swing bolt and hold down brackets; cartridge guides with screw-on cap, 0-60 psi pressure gauge with gauge guard, EPDM gaskets and drain plugs. All fasteners are SS. For use with DOE (Double Open End) cartridges

Features:

• Non-metallic solution contact CPVC, PVC or PP

• Heavy duty construction

• Pressure ratings to 80 psi

• Positive O-Ring seal at base and cover

• Cartridge guides with screw-on caps

• SS external hardware

• 0-60 psi pressure gauge with gauge guard

• From 12 to 60 – 10″ cartridge capacity

• Easy service Swing bolt cover closure

• Port size 1 1/2NPT or optional BSP

Material:

PVC, CPVC, PP

Performance :

12-125 gpm

SERIES ‘HD’ PLASTIC FILTER CHAMBERS

Specifications

SERIES ‘HD’ filter chambers are precision CNC machined from high purity PVDF or natural pure PP.

Chambers feature a swing bolt cover closure with ‘T’-handles for ease of cartridge service no tools are required. Precision machined covers feature FRP reinforcing plate to ensure positive liquid containment. Standard 0 – 60 psi gauge guard, vent valve and drain port are designed to simplify operation and maintenance. Standard flange connections are 1 1/2″ with rugged SS 316 back plates for ease of installation and to ensure leak-free operation. All external fasteners are SS 316; standard elastomers are EPDM. Chambers are designed for use with 4 – 10″, 20″, 30″ or 40″ SOE style filter cartridges.

Features:

• High purity non-metallic solution contact

• Proven durability and ease of service

• Standard heavy duty flange connections

• 0-60 psi gauge, air vent valve and drain port

• For use with standard 10″, 20″, 30″ or 40″ single open end (SOE) 222 style filter cartridges

• Flow rates to 150 gpm

Material:

PP, PVDF

Performance:

4-150 gpm

SERIES ‘HF’ PLASTIC FILTER CHAMBER

Specifications

SERIES ‘HF’ chambers feature precision CNC machined base and cover. The innovative base design has 3″ inlet and outlet ports providing low pressure differential. Base includes a 1″ plugged drain port for ease of maintenance. Cover includes vent valve, 0-60 psi pressure gauge with guard assembly, and SS cover plate. Cover is secured with swing bolts and ‘T’-handles (no tools are required to change cartridges). Shell is 18″ diameter and will hold 26 – 20″, 30″, 40″ or 50″* D.O.E. (double open end) style cartridges. Internals included are CPVC cross posts and PP cap springs to ensure proper cartridge location and eliminate solution bypass. Base, shell and cover are PVC for totally nonmetallic solution contact. Elastomers are EPDM and all external hardware is SS.

Features:

• Rugged construction, non-metallic solution contact

• Flows to 400 gpm

• High capacity – 26″ filter cartridges

• Standard 0-60 psi gauge with guard

• Low pressure drop – 4 psi @ 200 gpm

• ‘T’-handle cover closur

Material:

CPVC

Performance:

26-400 gpm

SERIES ‘GH-HP’ PLASTIC FILTER CHAMBERS

Specifications

For use with a variety of filter media (order separately)

– Depth wound, pleated, carbon or membrane cartridges

– Positive cartridge seal for:

Standard – DOE . . . Double Open End

Optional – SOE . . . Single Open End for 222 O-Ring

– Cleanable sleeves (used with or without precoat)

Features:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings to 140 psi

• Tee handles – No tools required

• Pressure gauge with vent valve

• High Pressure and High Flow

• SS tie rod cover closure & SS bracket

• Variety of sizes, From 4 to 55 – 10″ cartridge capacity

• Port sizes 1 1/2″, 2″ & 3″

• Gasket seal at cover and base

Material:

PVC, CPVC, PP, PVDF

Performance:

5-300 gpm high psi

SERIES ‘Y’ STEEL FILTER CHAMBER

Specifications

24 To 445 Filter Cartridges Or 12 To 89 Cleanable Sleeves

SERIES ‘Y’ filter chambers are made of carbon steel with vulcanized rubber or Hypalon lining to provide non -metallic solution contact for use with a wide range of chemical solutions. Corrosion resistance in each case is limited to the materials used in construction, including all components. It should be noted that corrosion resistance varies at different temperatures. Consult Bulletin TC-101 and Sales Department. These chambers are ideal for in-line applications or they can be used with a pump and motor filtration system for various chemical applications.

Features:

• Non-metallic solution contact Rubber or Hypalon lined, steel construction

• High flow rate – up to 10 G PM perfilter tube as applicable

• Large dirt holding capacity From 84 to 1557 sq .ft. w/ cartridges or 14 to 267 sq.ft. w/sleeves

• ASME code design – optional

• Weld ed construction

• Cartridge or precoat filtration

• Removable cage asse mbly Easy to service

• Flanged inlet, outlet and vent ports

Material:

Steel Rubber lined

Performance:

24-450 gpm

SERIES ‘GC’ PLASTIC FILTER CHAMBERS

Specifications

These filter chambers are designed for filtering process solutions where clarification will extend operating life and improve quality. Series ‘GC’ chambers feature a precision CNC machined base and molded cover. The innovative base design has 2″ inlet and outlet ports providing low pressure differential. The base includes 3/4″ plugged drain ports for ease of maintenance. The shell is cemented to the machined base to eliminate leakage and warping.

Features:

• Non-metallic solution contact

• Heavy duty construction

• High flow rate, low pressure drop 2″ connections

• High capacity 12 of 20″, 30″, 40″ or 50″ cartridges

• Easy to operate – swing bolts with ‘T’-handles

• 60 psi gauge, air vent valve and drain port

Material:

PVC, CPVC

Performance:

12-200 gpm