Serfilco VERTICAL PUMPS

Vertical Pumps

SERIES ‘E’ VERTICAL PUMPS

Specifications

The rugged Series ‘E’ sump pump is a tough, all machined pump designed for years of trouble-free operation. This pump features a cantilevered, sleeved SS shaft which eliminates bearings and seals, resulting in a pump that can run dry without damage. A vapor seal between the rotating shaft and the support column protects the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower. A unique characteristic of the Series ‘E’ pump is its ability to perform on continuous duty as a level control when an optional suction extension pipe is installed. With the motor energized, the pump will self-prime when liquid is above impeller level. The solution level will then be pumped down to the end of the suction extension, the pump will lose prime, then reprime when liquid again reaches the impeller. Discharge pipe assembly, suction extension and suction strainer are available options.

Features:

• Flows to 20 gpm or 15ft. TDH @ 60 Hz

• Non-metallic solution contact CPVC, PP, PVDF

• Dry operation will not damage pump

• Chemical duty motor – 1/8 HP

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Shaft vapor seal protects motor bearings and atmosphere

Material:

PP, CPVC, PVDF

Performance:

2-18 gpm

SERIES ‘EO ¾’ VERTICAL PUMP

Specifications

The Series ‘EO 3/4’ Pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. All models feature a cantilevered, sleeved SS shaft which eliminates bearing or bushing resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble free service. A vapor seal between the rotating shaft and the support column protects the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 20 gpm at 4 psi or 2 gpm at 23 psi

• Non-metallic solution contact PP, CPVC or 100% PVDF, FKM or EPDM elastomers

• Runs Dry – no bearings, bushings, spindles or liners to replace

• Centrifugal – quiet, vibration-free

• IN or OUT of-tank installation

• Will replace most OEM pumps

• Shaft vapor seals protects motor bearings and atmosphere

• Chemical duty motor (1/8 HP)

Material:

PP, CPVC, PVDF

Performance:

2-22 gpm

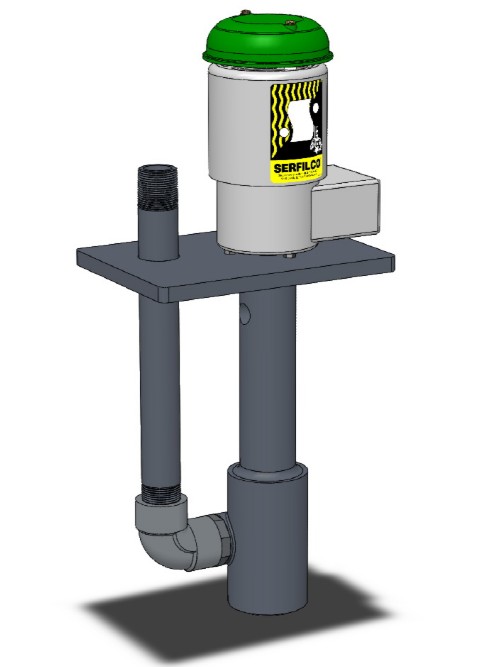

SERIES ‘EO 1’ VERTICAL PUMPS

Specifications

The Series ‘EO 1’ pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. The unique design of this pump includes a fully sleeved SS shaft threaded into a chemical duty motor. This eliminates weak shaft connections, pump bearings, spindles, bushings and liners, resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble-free service. Standard models include a heavy duty machined mounting plate with PTFE vapor seal and column labyrinth seal to protect the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 92 gpm or 68 ft. TDH @ 60 Hz (288 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PDX PP, CPVC or 100% PVDF FKM or EPDM elastomers

• Runs dry

• Chemical duty motor (1/3 – 1.5 HP) Sealed, oversized bearings, cast iron end bells. Corrosion resistant two-part epoxy enamel finish, SS nameplate. 1.15 service factor at 50 and 60 Hz.

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Will replace most OEM pumps

Material:

PP, CPVC, PVDF

Performance:

10-55 gpm

SERIES ‘EO 1¼’ VERTICAL PUMPS

Specifications

The Series ‘EO 1 1/4’ pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. The unique design of this pump includes a fully sleeved SS shaft threaded into a chemical duty motor. This eliminates weak shaft connections, pump bearings, spindles, bushings and liners, resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble-free service. Standard models include a heavy duty machined mounting plate with PTFE vapor seal and column labyrinth seal to protect the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 92 gpm or 68 ft. TDH @ 60 Hz (288 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PDX PP, CPVC or 100% PVDF FKM or EPDM elastomers

• Runs dry

• Chemical duty motor (1/3 – 1.5 HP) Sealed, oversized bearings, cast iron end bells. Corrosion resistant two-part epoxy enamel finish, SS nameplate. 1.15 service factor at 50 and 60 Hz.

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Will replace most OEM pumps

Material:

PP, CPVC, PVDF

Performance:

20-90 gpm

SERIES ‘EH’ VERTICAL PUMPS

Specifications

The Series ‘EH’ Sump Pump features a cantilevered, sleeved, SS shaft with vapor seal between the rotating shaft and the support column to further protect the motor.The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry without damage. A compound impeller prevents liquid from rising in the column, even at maximum TDH, while the fully-enclosed bottom impeller provides high hydraulic efficiency at low horsepower. A unique characteristic of all Series ‘EH’ pumps is their ability to lift solution with an optional suction extension pipe installed. With the motor energized, the pump will self-prime when liquid is at impeller level. The solution level will then be pumped down to the end of the suction extension to a maximum depth of 9 ft. (2.7m). The pump will lose prime, then automatically re-prime when liquid again reaches the impeller.

Features:

• Flows up to 185gpm or 145ft TDH @ 60 Hz

• Non-metallic solution contact – PPP, CPVC, PVDF, ECTFE

• Shaft vapor seal protects motor bearing and atmosphere

• Runs dry

• Chemical duty motor (1.0 – 7.5 HP)

• Centrifugal – quiet, vibration-free

• In or out-of-tank installation

• Choice of 12″ or 18″ column

• NPT or BSP connections

Material:

PP, CPVC, PVDF, ECTFE

Performance:

20-175 gpm

SERIES ‘EF’ VERTICAL PUMPS

Specifications

The Series ‘EF’ Vertical Pump represents the next generation of molded pumps from SERFILCO with flows to 400 gpm at 60 Hz. It is a robust design to meet the most demanding applications while providing the economy of operation found in all of our molded pumps. The ‘EF’ features a cantilevered, sleeved, SS shaft with vapor seal to provide protection for the motor. The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry indefinitely without damage. This pump is offered in a choice of our exclusive PPP high temperature polypropylene or CPVC construction and, as with all of our vertical cantilever pumps, provides non-metallic solution contact. A compound impeller prevents liquid from rising in the column even at maximum TDH, while the fully enclosed bottom impeller provides high hydraulic efficiency at low horsepower. A unique characteristic of our vertical cantilever pumps is their ability to lift solution with an optional suction extension installed. The pump self primes as long as liquid is at or above the level of the impeller. Once primed the solution will then be pumped down to the end of the suction extension to a maximum depth of 9 ft. (2.7m).

Features:

• Flows to 400 gpm or 170 FT. TDH @ 60 Hz

• Non-metallic solution contact PPP or CPVC

• Can run dry indefinitely

• Heavy duty PTFE vapor seal

• Centrifugal, quiet and vibration free

• In-tank or out-of-tank

• Chemical duty motor (7.5 – 15.0 HP)

• Column length 14″ or 17

Material:

CPVC, PP

Performance:

50-400 gpm

SERIES ‘EHM’ VERTICAL PUMPS

Specifications

The Series ‘EHM’ Vertical Pump features a cantilevered CPVC sleeved SS shaft with vapor seal between the rotating shaft and the support column to protect the motor. The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry without damage. A compound impeller prevents liquid from rising in the column while the fully-enclosed bottom impeller provides high hydraulic efficiency at low horsepower. The pump drive shaft is SS and is protected by a heavy duty CPVC impeller sleeve assembly. A vapor seal between the rotating shaft and pump column protects the motor and motor bearings. The complete pump assembly features non-metallic solution contact. The pump length from the underside of the mounting plate to the suction inlet is available as 15″ or 18″. The high efficiency impeller provides “pump-down” capabilities to 9 ft. below the inlet using a suction extension. FKM O-Rings, discharge pipe assembly and suction strainer are available as options.

Features:

• Non-metallic solution contact CPVC construction to 160°F

• To 650 gpm or 175 FT. TDH @ 60 Hz

• Can run dry indefinitely

• Heavy duty PTFE vapor seal

• In-tank or out-of-tank installation

• Chemical duty motor (7.5 – 20.0 HP)

• Includes PVC pump mounting plate

• Standard column lengths are 15″ and 18

Material:

CPVC

Performance:

60-650 gpm

SERIES ‘ESS’ & ‘ECI’ METAL VERTICAL PUMPS

Specifications

The Series ‘ESS’ and ‘ECI’ vertical pumps feature a high efficiency semi-open impeller, cast construction for superior strength and corrosion resistance, and a cantilevered SS 316 shaft guided by a graphite or Rulon bushing. This same bushing design and unique column assembly allows for reliable operation with columns up to 44″. The bushing is lubricated by the product being pumped, thus no external flushing liquid is required. However, since the bushing is being product flushed, these pumps must be used inside the tank. The optional heavy duty mounting plate uses a clamp arrangement which allows it to be positioned anywhere along the length of the pump column. The optional discharge pipe then fits through the mounting plate for easy drop-in installation. Pumps are constructed of SS 316 throughout for maximum corrosion resistance. Gasket is a synthetic fiber with cast iron, PTFE with 316 SS, shaft vapor seal is FKM. Shaft is available in four lengths to 44″. Graphite or Rulon shaft bushing provides vibration-free service and is located directly above the semi-enclosed high efficiency impeller, therefore, it is product flushed. Optional mounting plate can be clamped and tightened at any given point on the pump column, which allows the pump to be set at the desired depth. Motors are 3450 RPM @ 60 Hz or 2850 @ 50 Hz, TEFC or EXP, painted with two-part epoxy paint. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 180 gpm or 90 ft. TDH @ 60 Hz

• Available in13″, 20″, 32″ and 44″

• Available in two sizes – 1 1/4″ x 1″ and 2″ x 1 1/2″ NPT

• Motors are standard NEMA ‘C’ face (.75 – 5.0 HP)

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

Material:

Cast SS 316

Performance:

15-150 gpm

SERIES ‘HB’ SUMP VERTICAL PUMPS

Specifications

The Series ‘HB’ Sump Pump features corrosion resistant construction for deep sumps and chemical transfer. A SS shaft sleeved in CPVC offers unmatched strength and chemical resistance. A vapor seal between the rotating shaft and the pump column protects the motor and motor bearings. The shaft bearing and liner are positively lubricated with the product being pumped or clean water from a separate source by means of the bleed line. A spiral flush groove in the rotating bearing ensures a uniform flow of liquid across the bearing surface. The bearing liner is made of a special fluoride-resistant ceramic. A suction extension can be utilized to pump to depths below impeller level. Thus, a shor ter pump can be used, reducing shaft length and the number of bearings required.

Features:

• Flows to 140 gpm or 130ft. TDH @ 60 Hz (450 LPM or 28m @ 50 Hz)

• Corrosion resistant, CPVC construction

• Pump lengths: 2ft. to 10ft. (.6m to 3.6m)

• Water or product lubricated bearings

• Chemical duty motor with Sealed oversized bearings

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

• NPT or BSP connections

Material:

CPVC

Performance:

20-140 gpm

SERIES ‘B’ SUMP VERTICAL PUMPS

Specifications

The Series ‘B’ Pump features corrosion resistant construction for deep sumps and demanding conditions. An oversized machined pump housing is utilized allowing for high flow rates using low RPM motors, thus extending pump life. A SS shaft sleeved in CPVC offers unmatched strength and chemical resistance. A vapor seal between the rotating shaft and the pump column protects the motor and motor bearings. The shaft bearing and liner are positively lubricated with the product being pumped or clean water from a separate source by means of the bleed line. A spiral flush groove in the rotating bearing ensures a uniform flow of liquid across the bearing surface. The bearing liner is made of a special fluoride resistant ceramic. A suction extension can be utilized to pump to depths below impeller level. Thus, a shorter pump can be used, reducing shaft length and number of bearings required.

fEATURES:

• To 370 gpm or 84ft. TDH @ 60 Hz (1150 LPM or 18.5M @ 50 Hz)

• Pump lengths: 2ft. to 10ft. (.6M to 3.6M)

• Corrosion resistant, CPVC construction

• Water or product lubricated bearings

• Chemical duty

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

Material:

CPVC

Performance:

50-350 gpm