sERFILCO

(PLEASE CLICK ONE OF THE HEADINGS ABOVE TO JUMP DIRECTLY TO A SECTION)

SERIES ‘DP’ DRUM PUMPS

Specifications

SERIES ‘DP’ Drum Pumps combine modern manufacturing techniques with proven and reliable design features. They are a convenient and efficient capability of transferring and dispensing most liquid chemicals from drums, carboys and tanks. These pumps are available in a selection of engineered plastics or polished SS 316 thus providing a great range of chemical compatibility. The pumps are available in lengths to meet your requirements and all pumps can be used interchangeably with any of our electric or air motors. They can be quickly changed to meet particular pumping or motor requirements.

Features:

• Motor

• Pump tube assembly

• PVC hose: 6 ft.

• Dispensing nozzle

• Barrel adapter

• Storage bracket

• Digital flow Meter (opt.)

Material:

PP, PP, CPVC, PVDF, SS, CPVC/PVDF

Performance:

33 GPM

SERIES ‘HC’ HORIZONTAL PUMPS

Specifications

Series ‘HC’ pumps have 1″ FNPT suction x 3/4″ MNPT discharge and are available in CPVC or 100% PVDF. Series ‘HK’ pumps have 1 1/2″ MNPT suction x 1 1/2″ MNPT discharge and are available in CPVC with PVDF suction casing or 100% PVDF. Standard elastomers are FKM, EPDM is available. All models utilize a molded, semi-enclosed impeller. Mechanical seal is Type 21, externally mounted with SS components not in solution contact. Double mechanical seal is designed for flushing the seal chamber with water and is recommended for applications where abrasives or salts are present, or for conditions where metal deposition will occur. In addition, double water flush sealed pumps will permit dry run operation. Standard mechanical seal faces are silica-free ceramic/carbon (M1) and (M2). Silicon carbide seal faces (M8) are available and recommended for critical applications. Motors are chemical duty with sealed oversize earings, cast iron end bells, two-part epoxy finish, and SS tag. Motors are rated with 1.15 service factor at 50 or 60 Hz.

fEATURES:

• Flows to 78 gpm or 53′ TDH @ 60 Hz

• Non-metallic solution contact – CPVC or 100% PVDF

• Single or double mechanical seal Carbon/ceramic or silicon carbide EPDM or FKM elastomers

• Centrifugal – quiet, vibration-free

• Standard models provide non-overloading full flow with liquids to 1.2 S.G.

• Chemical duty motor (1/3 – 1-1/2 HP

Material:

CPVC, PVDF

Performance:

10-70 gpm

SERIES ‘HK’ HORIZONTAL PUMPS

Specifications

Series ‘HK’ Horizontal Pumps feature “total” chemical resistance with non-metallic construction of all wetted components. The molded, semi-enclosed impellers are designed to provide maximum pumping efficiency. These pumps feature external single seal or double water-flushed mechanical seal with choice of EPDM or FKM elastomer materials. Available close-coupled to minimize size or long-coupled with bearing pedestal base plate and motor. All closecoupled pumps are driven by chemical duty motors suitable for continuous duty in corrosive environments. Pumps are ideal for transferring and recirculating industrial solutions, plating solutions, process chemicals and other fluid handling applications.

fEATURES:

Flows to 78 gpm or 53 FT. TDH @ 60 Hz

• Non-metallic solution contact – CPVC or 100% PVDF

• Single or double mechanical seal

• Centrifugal – quiet, vibration-free

• Standard models provide non-overloading full flow with liquids to 1.2 S.G.

• Chemical duty motor (1/3 – 1-1/2 HP)

Material:

CPVC, PVDF

Performance:

10-70 gpm

SERIES ‘HH’ HORIZONTAL PUMPS

Specifications

Series ‘HH’ pumps are molded of natural CPVC or natural PVDF. They feature a volute designed for high TDH at high efficiency and all around optimum performance. The unique sleeved impeller design and non-metallic internally mounted mechanical seal combine to provide a compact assembly offering nonmetallic solution contact. Five impeller diameters provide a full range of flow and head performance with efficient use of motor horsepower. Motors are standard NEMA 56C, TEFC. For explosion-proof motors, consult Sales Department.

Pedestal mounted pump assemblies are available for 1/2 to 5 HP standard end bell motors. An optional long-coupled kit includes cast iron bearing, pedestal frame, flexible coupling, guard and FRP mounting channel.

fEATURES:

• Flows to 68 gpm or 167 ft. TDH @ 60 Hz

• Non-metallic solution contact CPVC, PVDF

• Single mechanical seal

• Connections: 1″ MNPT inlet and 3/4″ MNPT outlet

• Maximum solid size – .15″ (3.8mm)

mATERIAL:

CPVC, PVDF

Performance:

10-60 gpm

SERIES ‘K’ HORIZONTAL PUMPS

Specifications

Series ‘K’ centrifugal pumps are molded of high purity 100% natural color virgin PVDF. The resin is FDA approved and offers exceptionally high chemical resistance to strong acids and solvents. Semi-enclosed impeller provides efficient, trouble-free operation at all operating temperatures. Inlet and outlet connections are 1 1/2″ MNPT or sanitary flange. Unique design of carbon/ceramic mechanical seal isolates SS shaft from solution contact. The available (M3) seal component is silica-free ceramic which allows the pump to be used for solutions which contain fluorides . Seal elastomers and casing O-Ring are FKM. Casing clamp with “T” handle lock allows choice of discharge direction and ease of pump disassembly.

Features:

• Non-metallic solution contact 100% natural color PVDF for temperatures to 280°F (138°C)

• 1 1/2″ MNPT or sanitary connections

• Mounts to 56J motor

• Ideal for OEM applications

• Casing clamp for easy disassembly Provides choice of discharge direction

• To 80 gpm or 51 FT. TDH @ 60 Hz (252 LPM or 10.8m @ 50 Hz)

• Seal can be changed in 5 minutes

Material:

PVDF

Performance:

10-80 gpm

SERIES ‘HN’ HORIZONTAL PUMPS

Specifications

The Series ‘HN’ pump is capable of “total” chemical resistance, both internally and externally with its non-metallic construction of all wetted components. Engineering grade thermoplastics provide application compatibility with a variety of chemicals that would be corrosive to other materials of construction.

The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow/head requirements. The unique mechanical seal eliminates any metal in contact with the solution pumped. All of these features allow this pump to properly handle many applications at a fraction of the cost of exotic alloys.

Features:

• Non-metallic solution contact 30% glass-filled Noryl

• To 135 gpm or 88 ft. TDH @ 60 Hz

• Single mechanical seal carbon / silica-free ceramic EPDM or FKM elastomers

• Centrifugal – quiet, vibration-free

• Standard NEMA C face 56J TEFC motor

• 1 1/2″ x 1 1/2″ FNPT connections

• Back pull-out design, easy assembly and maintenance

Material:

Noryl

Performance:

20-120 gpm

SERIES ‘HE’ HORIZONTAL PUMPS

Specifications

The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow/head requirements.The external mechanical seal and impeller sleeve design isolates metal components to provide non-metallic solution contact with the pumped solution. The standard (M8) seal assembly has silicon carbide seal faces and is the most durable and longest lasting mechanical seal available. The double mechanical seal models require water lubrication of the seal faces and allows the pump to be used for solutions containing abrasives, high salt concentrations and for electroless plating solutions. Standard models are constructed of CPVC, PP, PVDF or ECTFE with threaded connections. Elastomers are EPDM or FKM. The mechanical seal is type 21, externally mounted with SS components not in solution contact. A double mechanical seal is recommended for solutions containing abrasives and for high temperature or other critical service. Close coupled motors are NEMA ‘JM’ or metric (IEC) standard. The motors designated NEMA can operate on 50 or 60 Hz at full rated horsepower.

Features:

• Flows to 175 gpm or 130′ TDH @ 60 Hz

• Non-metallic solution contact PPP, CPVC, PVDF or ECTFE

• Single or double mechanical seal

• Centrifugal – quiet, vibration-free

• NPT or metric connections available

• Chemical duty motor

Material:

PP, CPVC, PVDF, ECTFE

Performance:

20-175 gpm

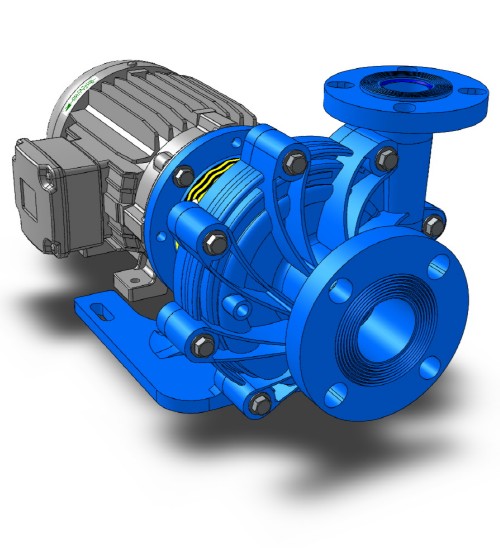

SERIES ‘HF’ HORIZONTAL PUMPS

Specifications

The Series ‘HF’ Horizontal pump represents the next generation of molded pumps from SERFILCO. The ‘HF’ retains a robust design and non-metallic solution contact to meet the most demanding applications while providing the choice of materials of construction and economy found in all of our molded pumps. The ‘HF’ is offered in a choice of our exclusive PPP high temperature polypropylene or CPVC construction and is ANSI dimensional with the optional flanged connections. The totally enclosed impeller is molded to close tolerances which allow this pump to operate at peak horsepower efficiency across a broad range of operational flow and head requirements. The external mechanical seal and impeller sleeve design isolates metal components to provide non-metallic solution contact with the pumped solution. The standard (M8) seal assembly has silicon carbide seal faces and is the most durable and longest lasting mechanical seal available. The double mechanical seal models require water lubrication of the seal faces and allows the pump to be used for solutions containing abrasives high salt concentrations and for electroless plating solutions.

Features:

• Non-metallic solution contact

• PPP high temperature polypropylene, CPVC or PVDF

• Centrifugal, quiet, vibration free

• Single or double mechanical seal with EPDM or FKM elastomers

• Chemical duty motor

• ANSI dimensional – with optional flanged connections

Material:

CPVC, PP, PVDF

Performance:

50-400 gpm

SERIES ‘H’ HORIZONTAL PUMPS

Specifications

The Series ‘H’ pump is a heavy-duty centrifugal pump machined from solid CPVC. It provides a high

level of resistance to aggressive chemicals. An external mechanical seal and sleeved shaft* provide excellent corrosion resistance. The new Series ‘H’ 6″ x 4″ pump features a titanium or Hastelloy C shaft. The Series ‘H’ pump serves as an economical alternative to ANSI style process pumps. The high flow rates, chemical resistance and durability of this pump make it the perfect workhorse for waste treatment, chemical processing, transfer and filter pumping. Pumps are available for long-coupling in the field to user supplied standard motors. Double seals are available and recommended forflushing the seal faces when abrasives are present or positive product containment is required. Optional coupling arrangements, mechanical seals, fittings and flange connections ensure adaptability to custom applications.

fEATURES:

• High flow rates Over 1200 gpm, or 149 ft. TDH @ 60 Hz (3800 l/min or 31.5m @ 50 Hz)

• Excellent chemical resistance Machined from solid CPVC

• Single or double mechanical seal Silicon carbide EPDM or FKM elastomers

• Quiet, vibration free Centrifugal, high efficiency enclosed impeller

• Flanged or NPT ports:

• Long or close-coupled Back pull-out design. Optional long-coupled kit available

• Standard chemical duty motors (3 – 30 HP)

• Sealed oversized bearings, cast iron end bells, shaft slinger washer, corrosion resistant twopart epoxy

Material:

CPVC

Performance:

1200 gpm

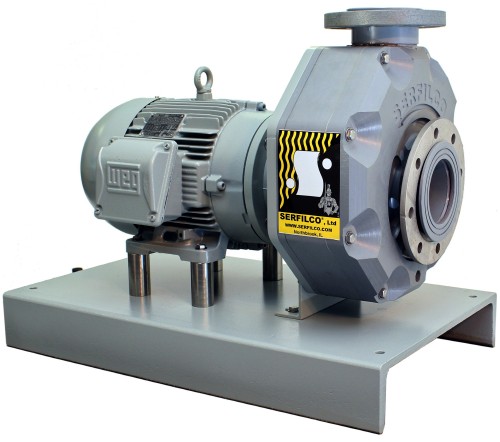

SERIES ‘HA’ HORIZONTAL PUMPS

Specifications

The Series ‘HA’ is a heavy-duty, ANSI dimensional horizontal pump engineered for utmost reliability in severe chemical applications. The pump is machined from solid CPVC and utilizes an externally mounted mechanical seal. The 3x2x6 and 4x3x8 pumps have sleeved shafts for non-metallic solution contact while the 4x3x10 and 6x4x10 pumps utilize titanium or Hastelloy C shafts. This proven design provides excellent resistance to aggressive chemicals as well as economical and reliable operation for many years of service. The Series ‘HA’ horizontal pump is available in four sizes with flow rates to 1200 gpm (3800 LPM), and is available with single or double mechanical seals and EPDM or FKM elastomers. Larger sized pumps designed to achieve 2400 gpm are in development. The standard configuration for these pumps is close coupled, however certain models are available long-coupled. The Series ‘HA’ pump with its high flow rates, chemical resistance and durability makes it the perfect “workhorse” for chemical processing, transfer and filter pumping, fume scrubbers and cooling towers or for waste treatment applications.

Features:

• Flows to 1200 gpm or 155′ TDH @ 60 Hz

• Excellent chemical resistance

• Machined from solid CPVC

• Centrifugal, quiet, vibration free

• Single or double mechanical seal with EPDM or FKM elastomers

• Long or close-coupled

• Chemical duty motor

Material:

CPVC

Performance:

100-1200 gpm

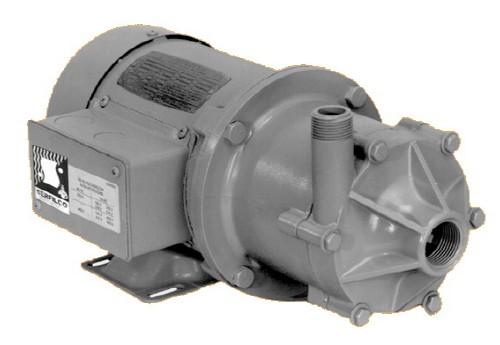

SERIES ‘HCI’ HORIZONTAL PUMPS

Specifications

The Series ‘HCI’ horizontal pumps feature compact close-coupled design. A high efficiency semi-open impeller allows for less clogging and quick cleaning. Since the components are cast, there are no welds to break. Also, cast construction provides a superior corrosion resistance over similar welded styles. The Series ‘HCI’ pumps feature the most widely accepted industrial mechanical seal designated as Type 21. This seal is mounted “inboard” and, thus tends to be self-cleaning. The seal is available as a single seal solution flush or as a double seal which uses external liquid as a flush. By adding the double seal, these pumps can better handle abrasives / salts and be protected from running dry. Pumps are constructed of cast iron for maximum corrosion resistance. Gasket is a synthetic fiber with cast iron. Both the single and double inboard seal assemblies are available in either EPDM or FKM. Double seal is recommended for flushing the seal chamber with water when abrasives are present or for certain other critical conditions. The SS shaft adapter protects the motor shaft and allows the use of standard NEMA motor. Motors are 3450 RPM @ 60Hz or 2850 RPM @50 Hz, TEFC or EXP. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 160 U. S. gpm or 90 ft. TDH @ 60 Hz (510 LPM or 19.5m @ 50 Hz)

• Cast iron solution contact

• Single or double mechanical seal Carbon/ceramic FKM or EPDM elastomers

• SS 316 shaft adapter

• Centrifugal, quiet, vibration-free

• Includes steel mounting base

• Motors are standard NEMA ‘C’ face TEFC or explosion-proof

Material:

Cast iron, Cast SS316

Performance:

10-160 gpm

SERIES ‘HSS’ HORIZONTAL PUMPS

Specifications

The Series ‘HSS’ horizontal pumps feature compact close-coupled design. A high efficiency semi-open impeller allows for less clogging and quick cleaning. Since the components are cast, there are no welds to break. Also, cast construction provides a superior corrosion resistance over similar welded styles. The Series ‘HSS’ pumps feature the most widely accepted industrial mechanical seal designated as Type 21. This seal is mounted “inboard” and, thus tends to be self-cleaning. The seal is available as a single seal solution flush or as a double seal which uses external liquid as a flush. By adding the double seal, these pumps can better handle abrasives / salts and be protected from running dry. Pumps are constructed of SS 316 for maximum corrosion resistance. Gasket is PTFE with SS 316. Both the single and double inboard seal assemblies are available in either EPDM or FKM. Double seal is recommended for flushing the seal chamber with water when abrasives are present or for certain other critical conditions. The SS shaft adapter protects the motor shaft and allows the use of standard NEMA motor. Motors are 3450 RPM @ 60Hz or 2850 RPM @50 Hz, TEFC or EXP. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 160 U.S. gpm or 90 ft. TDH @ 60 Hz

• All SS 316 solution contact

• Single or double mechanical seal Carbon/ceramic FKM or EPDM elastomers

• SS 316 shaft adapter

• Centrifugal, quiet, vibration-free

• Includes steel mounting base

• Motors are standard NEMA ‘C’ face TEFC or explosion-proof

Material:

Cast SS316

Performance:

10-160 gpm

SERIES ‘RC’ HORIZONTAL PUMPS

Specifications

The Series ‘RC’ horizontal pump is a compact close-coupled design. A high efficiency, semi-open cast iron impeller allows for less clogging and quick cleaning. The components are cast so there are no welds to break. In addition, the cast iron construction provides improved corrosion resistance over similar welded styles. The Series ‘RC’ pump is available with a choice of mechanical seals, Type 21 single or double. The seal is mounted “in-board” and, thus tends to be self-cleaning. It is available as a single seal solution flush or as a double seal which requires external liquid to flush. When ordered with a double seal, the pump will better handle abrasives, solutions which tend to crystallize, and dry run operation. Series ‘RC’ pumps are constructed of cast iron with a synthetic fiber gasket. Standard pumps feature EPDM or FKM elastomers with ceramic and carbon seal faces. These pumps use a standard NEMA C face motor. Motors are TEFC, 3450 RPM @ 60 Hz or 2850 RPM @ 50 Hz.

Features:

• Flows to 420 gpm or 82 ft. TDH @ 60 Hz (1325 LPM or 17.4m @ 50 Hz)

• SS 316 shaft, cast iron mounting bracket

• Single or double mechanical seal Carbon/ceramic EPDM or FKM elastomers

• Centrifugal, quiet, vibration-free

• Motors are standard NEMA C face, TEFC

Material:

Cast Iron

Performance:

50-400 gpm

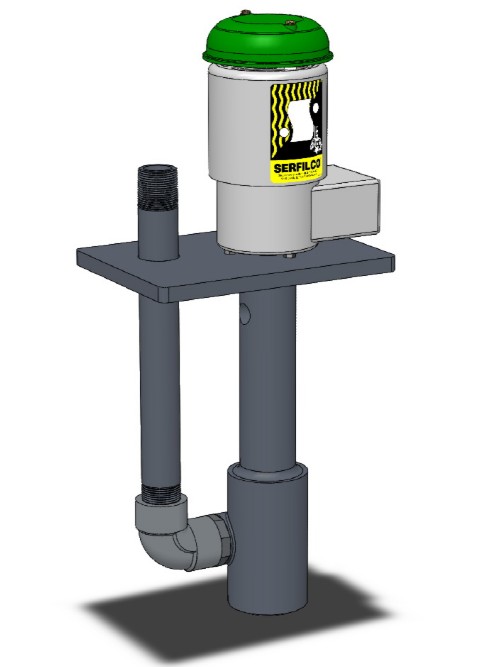

SERIES ‘E’ VERTICAL PUMPS

Specifications

The rugged Series ‘E’ sump pump is a tough, all machined pump designed for years of trouble-free operation. This pump features a cantilevered, sleeved SS shaft which eliminates bearings and seals, resulting in a pump that can run dry without damage. A vapor seal between the rotating shaft and the support column protects the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower. A unique characteristic of the Series ‘E’ pump is its ability to perform on continuous duty as a level control when an optional suction extension pipe is installed. With the motor energized, the pump will self-prime when liquid is above impeller level. The solution level will then be pumped down to the end of the suction extension, the pump will lose prime, then reprime when liquid again reaches the impeller. Discharge pipe assembly, suction extension and suction strainer are available options.

Features:

• Flows to 20 gpm or 15ft. TDH @ 60 Hz

• Non-metallic solution contact CPVC, PP, PVDF

• Dry operation will not damage pump

• Chemical duty motor – 1/8 HP

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Shaft vapor seal protects motor bearings and atmosphere

Material:

PP, CPVC, PVDF

Performance:

2-18 gpm

SERIES ‘EO ¾’ VERTICAL PUMP

Specifications

The Series ‘EO 3/4’ Pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. All models feature a cantilevered, sleeved SS shaft which eliminates bearing or bushing resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble free service. A vapor seal between the rotating shaft and the support column protects the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 20 gpm at 4 psi or 2 gpm at 23 psi

• Non-metallic solution contact PP, CPVC or 100% PVDF, FKM or EPDM elastomers

• Runs Dry – no bearings, bushings, spindles or liners to replace

• Centrifugal – quiet, vibration-free

• IN or OUT of-tank installation

• Will replace most OEM pumps

• Shaft vapor seals protects motor bearings and atmosphere

• Chemical duty motor (1/8 HP)

Material:

PP, CPVC, PVDF

Performance:

2-22 gpm

SERIES ‘EO 1’ VERTICAL PUMPS

Specifications

The Series ‘EO 1’ pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. The unique design of this pump includes a fully sleeved SS shaft threaded into a chemical duty motor. This eliminates weak shaft connections, pump bearings, spindles, bushings and liners, resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble-free service. Standard models include a heavy duty machined mounting plate with PTFE vapor seal and column labyrinth seal to protect the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 92 gpm or 68 ft. TDH @ 60 Hz (288 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PDX PP, CPVC or 100% PVDF FKM or EPDM elastomers

• Runs dry

• Chemical duty motor (1/3 – 1.5 HP) Sealed, oversized bearings, cast iron end bells. Corrosion resistant two-part epoxy enamel finish, SS nameplate. 1.15 service factor at 50 and 60 Hz.

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Will replace most OEM pumps

Material:

PP, CPVC, PVDF

Performance:

10-55 gpm

SERIES ‘EO 1¼’ VERTICAL PUMPS

Specifications

The Series ‘EO 1 1/4’ pump benefits from proven design features gained through over 30 years of experience in developing chemically resistant vertical pumps. The unique design of this pump includes a fully sleeved SS shaft threaded into a chemical duty motor. This eliminates weak shaft connections, pump bearings, spindles, bushings and liners, resulting in a chemical duty pump which can run dry indefinitely, providing years of trouble-free service. Standard models include a heavy duty machined mounting plate with PTFE vapor seal and column labyrinth seal to protect the motor. The compound impeller prevents liquid from rising in the column, even at maximum TDH, while the semi-enclosed bottom impeller provides efficient flow performance at low horsepower.

Features:

• Flows to 92 gpm or 68 ft. TDH @ 60 Hz (288 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PDX PP, CPVC or 100% PVDF FKM or EPDM elastomers

• Runs dry

• Chemical duty motor (1/3 – 1.5 HP) Sealed, oversized bearings, cast iron end bells. Corrosion resistant two-part epoxy enamel finish, SS nameplate. 1.15 service factor at 50 and 60 Hz.

• Centrifugal – quiet, vibration-free

• In- or out-of-tank installation

• Will replace most OEM pumps

Material:

PP, CPVC, PVDF

Performance:

20-90 gpm

SERIES ‘EH’ VERTICAL PUMPS

Specifications

The Series ‘EH’ Sump Pump features a cantilevered, sleeved, SS shaft with vapor seal between the rotating shaft and the support column to further protect the motor.The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry without damage. A compound impeller prevents liquid from rising in the column, even at maximum TDH, while the fully-enclosed bottom impeller provides high hydraulic efficiency at low horsepower. A unique characteristic of all Series ‘EH’ pumps is their ability to lift solution with an optional suction extension pipe installed. With the motor energized, the pump will self-prime when liquid is at impeller level. The solution level will then be pumped down to the end of the suction extension to a maximum depth of 9 ft. (2.7m). The pump will lose prime, then automatically re-prime when liquid again reaches the impeller.

Features:

• Flows up to 185gpm or 145ft TDH @ 60 Hz

• Non-metallic solution contact – PPP, CPVC, PVDF, ECTFE

• Shaft vapor seal protects motor bearing and atmosphere

• Runs dry

• Chemical duty motor (1.0 – 7.5 HP)

• Centrifugal – quiet, vibration-free

• In or out-of-tank installation

• Choice of 12″ or 18″ column

• NPT or BSP connections

Material:

PP, CPVC, PVDF, ECTFE

Performance:

20-175 gpm

SERIES ‘EF’ VERTICAL PUMPS

Specifications

The Series ‘EF’ Vertical Pump represents the next generation of molded pumps from SERFILCO with flows to 400 gpm at 60 Hz. It is a robust design to meet the most demanding applications while providing the economy of operation found in all of our molded pumps. The ‘EF’ features a cantilevered, sleeved, SS shaft with vapor seal to provide protection for the motor. The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry indefinitely without damage. This pump is offered in a choice of our exclusive PPP high temperature polypropylene or CPVC construction and, as with all of our vertical cantilever pumps, provides non-metallic solution contact. A compound impeller prevents liquid from rising in the column even at maximum TDH, while the fully enclosed bottom impeller provides high hydraulic efficiency at low horsepower. A unique characteristic of our vertical cantilever pumps is their ability to lift solution with an optional suction extension installed. The pump self primes as long as liquid is at or above the level of the impeller. Once primed the solution will then be pumped down to the end of the suction extension to a maximum depth of 9 ft. (2.7m).

Features:

• Flows to 400 gpm or 170 FT. TDH @ 60 Hz

• Non-metallic solution contact PPP or CPVC

• Can run dry indefinitely

• Heavy duty PTFE vapor seal

• Centrifugal, quiet and vibration free

• In-tank or out-of-tank

• Chemical duty motor (7.5 – 15.0 HP)

• Column length 14″ or 17

Material:

CPVC, PP

Performance:

50-400 gpm

SERIES ‘EHM’ VERTICAL PUMPS

Specifications

The Series ‘EHM’ Vertical Pump features a cantilevered CPVC sleeved SS shaft with vapor seal between the rotating shaft and the support column to protect the motor. The cantilevered shaft eliminates bearings and conventional pump seals, resulting in a pump that can run dry without damage. A compound impeller prevents liquid from rising in the column while the fully-enclosed bottom impeller provides high hydraulic efficiency at low horsepower. The pump drive shaft is SS and is protected by a heavy duty CPVC impeller sleeve assembly. A vapor seal between the rotating shaft and pump column protects the motor and motor bearings. The complete pump assembly features non-metallic solution contact. The pump length from the underside of the mounting plate to the suction inlet is available as 15″ or 18″. The high efficiency impeller provides “pump-down” capabilities to 9 ft. below the inlet using a suction extension. FKM O-Rings, discharge pipe assembly and suction strainer are available as options.

Features:

• Non-metallic solution contact CPVC construction to 160°F

• To 650 gpm or 175 FT. TDH @ 60 Hz

• Can run dry indefinitely

• Heavy duty PTFE vapor seal

• In-tank or out-of-tank installation

• Chemical duty motor (7.5 – 20.0 HP)

• Includes PVC pump mounting plate

• Standard column lengths are 15″ and 18

Material:

CPVC

Performance:

60-650 gpm

SERIES ‘ESS’ & ‘ECI’ METAL VERTICAL PUMPS

Specifications

The Series ‘ESS’ and ‘ECI’ vertical pumps feature a high efficiency semi-open impeller, cast construction for superior strength and corrosion resistance, and a cantilevered SS 316 shaft guided by a graphite or Rulon bushing. This same bushing design and unique column assembly allows for reliable operation with columns up to 44″. The bushing is lubricated by the product being pumped, thus no external flushing liquid is required. However, since the bushing is being product flushed, these pumps must be used inside the tank. The optional heavy duty mounting plate uses a clamp arrangement which allows it to be positioned anywhere along the length of the pump column. The optional discharge pipe then fits through the mounting plate for easy drop-in installation. Pumps are constructed of SS 316 throughout for maximum corrosion resistance. Gasket is a synthetic fiber with cast iron, PTFE with 316 SS, shaft vapor seal is FKM. Shaft is available in four lengths to 44″. Graphite or Rulon shaft bushing provides vibration-free service and is located directly above the semi-enclosed high efficiency impeller, therefore, it is product flushed. Optional mounting plate can be clamped and tightened at any given point on the pump column, which allows the pump to be set at the desired depth. Motors are 3450 RPM @ 60 Hz or 2850 @ 50 Hz, TEFC or EXP, painted with two-part epoxy paint. Single phase TEFC motors include 8 ft. (2.4m) line cord.

Features:

• Flows to 180 gpm or 90 ft. TDH @ 60 Hz

• Available in13″, 20″, 32″ and 44″

• Available in two sizes – 1 1/4″ x 1″ and 2″ x 1 1/2″ NPT

• Motors are standard NEMA ‘C’ face (.75 – 5.0 HP)

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

Material:

Cast SS 316

Performance:

15-150 gpm

SERIES ‘HB’ SUMP VERTICAL PUMPS

Specifications

The Series ‘HB’ Sump Pump features corrosion resistant construction for deep sumps and chemical transfer. A SS shaft sleeved in CPVC offers unmatched strength and chemical resistance. A vapor seal between the rotating shaft and the pump column protects the motor and motor bearings. The shaft bearing and liner are positively lubricated with the product being pumped or clean water from a separate source by means of the bleed line. A spiral flush groove in the rotating bearing ensures a uniform flow of liquid across the bearing surface. The bearing liner is made of a special fluoride-resistant ceramic. A suction extension can be utilized to pump to depths below impeller level. Thus, a shor ter pump can be used, reducing shaft length and the number of bearings required.

Features:

• Flows to 140 gpm or 130ft. TDH @ 60 Hz (450 LPM or 28m @ 50 Hz)

• Corrosion resistant, CPVC construction

• Pump lengths: 2ft. to 10ft. (.6m to 3.6m)

• Water or product lubricated bearings

• Chemical duty motor with Sealed oversized bearings

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

• NPT or BSP connections

Material:

CPVC

Performance:

20-140 gpm

SERIES ‘B’ SUMP VERTICAL PUMPS

Specifications

The Series ‘B’ Pump features corrosion resistant construction for deep sumps and demanding conditions. An oversized machined pump housing is utilized allowing for high flow rates using low RPM motors, thus extending pump life. A SS shaft sleeved in CPVC offers unmatched strength and chemical resistance. A vapor seal between the rotating shaft and the pump column protects the motor and motor bearings. The shaft bearing and liner are positively lubricated with the product being pumped or clean water from a separate source by means of the bleed line. A spiral flush groove in the rotating bearing ensures a uniform flow of liquid across the bearing surface. The bearing liner is made of a special fluoride resistant ceramic. A suction extension can be utilized to pump to depths below impeller level. Thus, a shorter pump can be used, reducing shaft length and number of bearings required.

fEATURES:

• To 370 gpm or 84ft. TDH @ 60 Hz (1150 LPM or 18.5M @ 50 Hz)

• Pump lengths: 2ft. to 10ft. (.6M to 3.6M)

• Corrosion resistant, CPVC construction

• Water or product lubricated bearings

• Chemical duty

• Centrifugal – quiet, vibration-free

• Shaft vapor seal protects motor bearings and atmosphere

Material:

CPVC

Performance:

50-350 gpm

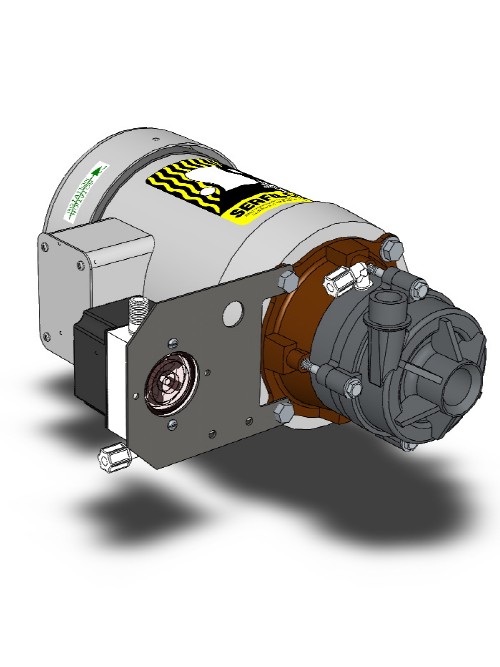

SERIES ‘A MAG’ MAGNETIC COUPLED PUMPS

Specifications

The Series ‘A’ magnetic coupled pumps are seal-less and leak proof, providing total solution and vapor containment. These pumps feature a shaft and bearing free design that allows them to be used for electroless solutions. The impeller magnet assembly floats in the radial magnetic field set up by the external drive magnet, eliminating the need for a shaft or spindle. The pump body can be rotated to selected direction of discharge. Neutralizing fluid will normally flush the interior adequately without need for disassembly. Impellers supplied on all standard seal-less pumps are suitable for water-like liquids up to 1.2 specific gravity.

Liquids with a higher specific gravity can be pumped if:

1. The outlet flow is restricted so the impeller magnet stays synchronized with the drive magnet.

2. The restrictions from a filter or other source of discharge head loss are sufficient to keep the impeller and drive magnets synchronized.

3. The overall diameter of the impeller is reduced

FEATURES:

• Flows to 9 gpm or 19 ft. TDH @ 60 Hz

• Non-metallic solution contact PP, CPVC, PVDF or ECTFE

• Continuous duty design

• Quiet, economical, centrifugal

• Low maintenance No spindles, bearings or thrust washers

mATERIAL:

PP, CPVC, PVDF, ECTFE

PERFORMANCE:

1-9 gpm

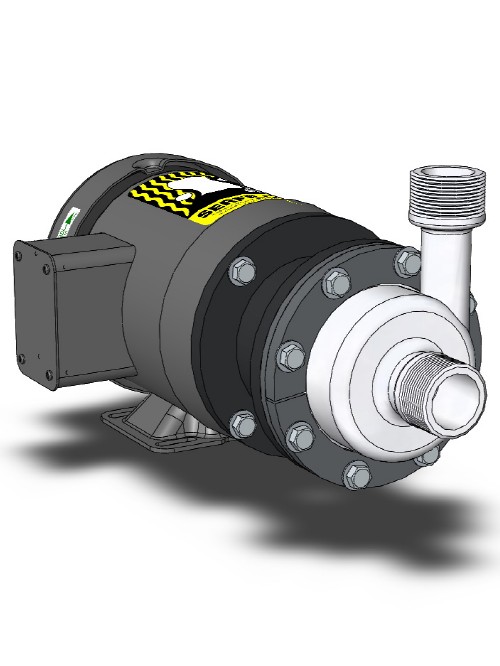

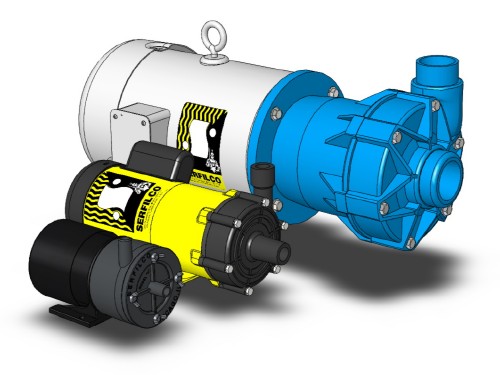

SERIES ‘B MAG’ MAGNETIC COUPLED PUMPS

Specifications

The Series ‘B Mag’ magnetic coupled pumps are sealless and leakproof, providing total solution and vapor containment. These pumps feature a shaft and bearing free design that allows them to be used for electroless solutions. The impeller magnet assembly floats in the radial magnetic field set up by the external drive magnet, eliminating the need for a shaft or spindle. The pump body can be rotated to selected direction of discharge. Neutralizing fluid will normally flush the interior adequately without need for disassembly. Impellers supplied on all standard seal-less pumps are suitable for water-like liquids up to 1.2 specific gravity.

Liquids with a higher specific gravity can be pumped if:

1. The outlet flow is restricted so the impeller magnet stays synchronized with the drive magnet.

2. The restrictions from a filter or other source of discharge head loss are sufficient to keep the impeller and drive magnets synchronized.

3. The overall diameter of the impeller is reduced

Features:

• Flows to 12 gpm or 24 ft. TDH @ 60 Hz

• Non-metallic solution contact PP, CPVC, PVDF or ECTFE

• Continuous duty design

• Quiet, economical, centrifugal

• Low maintenance No spindles, bearings or thrust washers

Material:

PP, CPVC, PVDF, ECTFE

Performance:

2-14 gpm

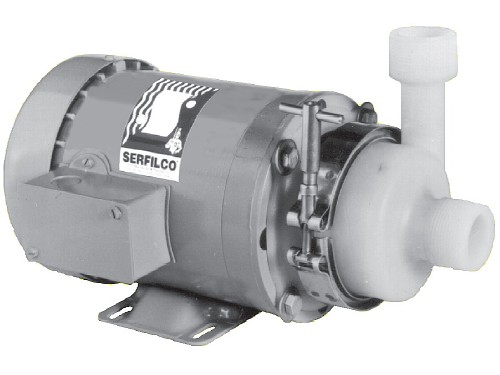

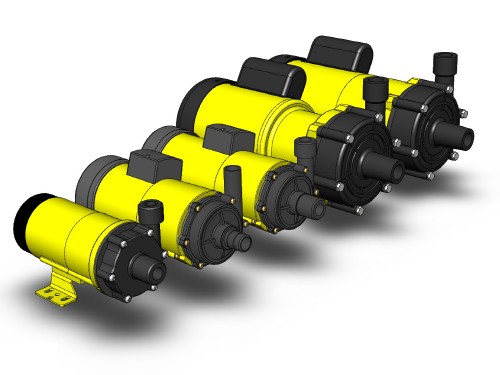

SERIES ‘X’ MAGNETIC COUPLED PUMPS

Specifications

SERIES ‘X’ Magnetic Coupled Pumps are the latest in magnetic coupled pump technology. Tested and proven design features provide a pump that is seal-less and leakproof. Available materials of construction and flow capacities from 1 to 25 gpm make these pumps an excellent choice for a wide variety of applications from water at ambient temperatures to harsh chemicals at elevated temperatures. Standard ‘X’ models have strong magnets and powerful, highly efficient continuous duty motors which allow them to operate non-overloading and provide continuous flow with liquids up to 1.3 specific gravity. Compact and quiet Series ‘X’ pumps are designed to provide years of trouble-free operation. The following information covers standard Series ‘X’ models.

Features:

• Flows from 1 to 25 gpm @ 60 Hz (3 – 78 LPM @ 50 Hz)

• Non-metallic solution contact PP, PVDF, ETFE, FKM

• NPT or hose barb connections

• Strong magnets will handle liquids to 1.3 specific gravity

• Continuous duty design

• Compact, quiet and efficient

• UL recognized, Œ conforming

• Motors are available 100-110V/1/50-60 Hz or 230V/1/50-60 Hz

• Designed to replace similar OEM pumps

Material:

PP, PVDF

Performance:

1-25 gpm

SERIES ‘M’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘M’ Magnetic-Coupled Pumps are seal-less and “leak-proof”, providing total solution and vapor containment. They are available in two different materials of construction for a wide range of chemical and temperature compatibility. The relationship of the impeller magnet to the liner reflects an advanced design which allows extended operation at dry run or during loss of prime without causing damage to the pump. The impeller head is separate from the impeller magnet hub for field interchangeability. The mouth ring design eliminates the need for a front thrust washer. By using rare-earth magnets, this pump provides flow and pressure equal to that of a physically much larger pump. This powerful coupling allows the pump to operate at full flow with the full size impeller while handling liquids up to 1.6 S.G. @ 30 CPS.

features:

• Flows to 70 gpm or 56 ft. TDH @ 60 Hz (220 LPM or 12m @ 50 Hz)

• Non-metallic solution contact Glass reinforced PP or carbon reinforced PVDF

• Extended dry run Unique design helps prevent pump damage

• Powerful rare-earth magnets Provide sure coupling to 1.6 S.G. @ 30 CPS

• Connections NPT or BSP Optional: 1/4″ NPT drain

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

10-70 gpm

SERIES ‘D’ MAGNETIC COUPLED PUMPS

Specifications

SERIES ‘D’ Magnetic Coupled Pumps are seal-less, providing for maintenance-free and “leak-proof” operation. The magnetic coupling acts as a clutch to provide overload protection. The broad range of construction materials allows for a variety of applications and service with most corrosive solutions. The impeller magnet assembly floats in the radial magnetic field set up by the motor driven external drive magnet. The impeller is designed to deliver the maximum flow and pressure utilizing the available strength of the synchronized magnets. The standard diameter impeller is suitable for waterlike liquids to 1.1 specific gravity. Liquids having a higher specific gravity can be pumped if the overall diameter of the impeller is reduced, the outlet flow is restricted,or the restrictions from a filter or other head loss is sufficient to keep the impeller magnet in synchronization.

Features:

SEAL-LESS and LEAK-PROOF for total solution containment reliable, trouble-free pumping

• Corrosion resistant PP, PVDF, PPS SS316

• Centrifugal – quiet, vibration-free

• Flows to 53 gpm or 58 FT. TDH @ 60 Hz

• Maximum liquid temperature

PP and PPS: 150°F

PVDF: 220°F, SS316 : 250°F

material:

PP, PVDF

Performance:

5-45 gpm

SERIES ‘ME’ MAGNETIC COUPLED PUMPS

Specifications

Standard models are constructed of glass-fiber reinforced polypropylene or carbon-fiber reinforced PVDF for suction casing, magnet liner and impeller. Impeller magnets are encapsulated in unfilled polypropylene or unfilled PVDF. The front and rear thrust rings and shaft are high purity, fluoride resistance alumina ceramic.

The impeller thrust ring is molybdenum disulfide filled PTFE. The casing ‘O’-ring is Viton. Maximum pump pressure; 80 PSI (5.4 bar). Motors are continuous-duty and have a 1.15 service factor. Single phase motors are supplied with 8ft (2.4m) of 3-wire cord and plug.

Features:

• Flows to 95 GPM or 54 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Glass reinforced polypropylene or carbon reinforced PVDF

• High operating efficiency up to 70%

• Capable of running dry without damage

• Powerful rare earth magnets

• Choice of connections: NPT or BSP threads, flanges or unions.

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

95 gpm

SERIES ‘MES’ MAGNETIC COUPLED PUMPS

Specifications

Standard models are constructed of glass-fiber reinforced polypropylene or carbon-fiber reinforced PVDF for suction casing, magnet liner and impeller. Impeller magnets are encapsulated in unfilled polypropylene or unfilled PVDF. The front and rear thrust rings and shaft are high purity, fluoride resistance alumina ceramic.

The impeller thrust ring is molybdenum disulfide filled PTFE. The casing ‘O’-ring is FKM. Maximum pump pressure; 80 PSI (5.5 bar). Motors are continuous-duty and have a 1.5 service factor.

Features:

• Flows to 54 GPM or 63 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Polypropylene or Carbon reinforced PVDF

• Deep-lift capacity Up to 25 feet / 7.6 meters

• Fast priming 18 feet / 4.6 meters in 90 sec.

• Extended dry run capability

• Powerful rare earth magnets

• Accepts standard motors

Material:

PP, PVDF

Performance:

54 gpm

SERIES ‘F’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘F’ Magnetic-Coupled Pumps are seal-less and “leak-proof” providing total solution containment. Available in two different materials of construction for a wide range of chemical and temperature compatibility. By using powerful rare-earth magnets, this pump provides flow and pressure equal to that of a physically much larger pump. This powerful coupling allows the pump to operate with the full size impeller at full flow while handling liquids up to 1.8 S.G. or 50 CPS. These powerful magnets create a balancing field which eliminates loading on bearing surfaces, thus providing an extended life span of the bushing compared to that of many standard magnetic coupled pumps. This same “balancing” gives the pump its ability to run dry for 10 minutes, or 30 minutes if wetted, before damage occurs. A fluted bushing provides positive internal liquid circulation/flush along the shaft spindle. These pumps utilize a high-purity ceramic stub-shaft which eliminates breakage. A unique feature of this pump is its ability to mount to NEMA and metric frame motors, thus giving motor options of TEFC, EXP, chemical duty and 575V. The pump is also available longcoupled.

Features:

• Flows to 255 gpm or 135 ft. TDH @ 60 Hz (804 LPM or 28.6m @ 50 Hz)

• Non-metallic solution contact Glass reinforced PP or Carbon reinforced PVDF

• Can run dry for 10 minutes, or 30 minutes if wetted, without causing pump damage

• Powerful rare earth magnets Provide sure coupling to 1.8 S.G.

• Accepts standard motors NEMA or IEC metric (except 143/145 frame)

Material:

PP, PVDF

Performance:

25-200 gpm

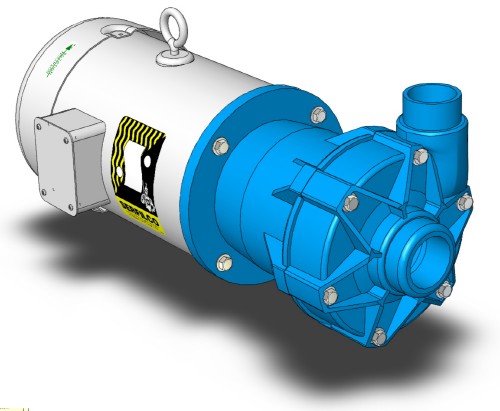

SERIES ‘FE’ MAGNETIC COUPLED PUMPS

Specifications

Series ‘FE’ magnetic coupled pumps are seal-less and “leak-proof”, providing total solution containment. They are available in a choice of two different corrosion resistant materials for a wide range of chemical and temperature compatibility and are ideal for handling even the most difficult applications. The Series ‘FE’ magnetic coupled pumps offer extremely high operating efficiencies for their size; up to 70%. This technological advancement results in smaller motor horsepower and means lower energy consumption and operating costs over the long life cycle of the pump. These pumps utilize powerful rare earth magnets which allow them to operate at full flow with a full size impeller while handling liquids over 1.8 specific gravity. Additionally the Series ‘FE’ is capable of running dry without damage when equipped with the standard carbon bushing and under optimum operating conditions. This helps protect the pump from operator errors and system upsets

Features:

• Flows to 130 gpm or 97 ft. TDH @ 60 Hz

• Non-metallic solution contact

• High operating efficiency – up to 70%

• Capable of running dry without damage

• Powerful rare earth magnets Provide sure coupling

• Choice of connections – NPT, BSP, flanges or unions

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

Performance:

15-130 gpm

SERIES ‘FES’ SELF PRIMING MAGNETIC COUPLED PUMPS

Specifications

Series ‘FES’ self-priming magnetic coupled pumps are seal-less and “leak-proof” providing total solution containment. They are available in a choice of two different corrosion resistant materials for a wide range of chemical and temperature compatibility and are ideal for handling even the most difficult applications. The outstanding self-priming feature of the Series ‘FES’ combines deep-lift capabilities (up to 25 feet) and lightning-fast priming (18 feet in 90 seconds). The priming chamber’s gooseneck design eliminates the need for internal check valves while ensuring that enough liquid is retained for efficient re-priming. These pumps utilize powerful rare earth magnets which allow them to operate at full flow with a full size impeller while handling liquids over 1.8 specific gravity. Additionally the Series ‘FES’ is capable of running dry without damage when equipped with the standard carbon bushing and under optimum operating conditions. Their innovative and highly efficient design, and low energy consumption make these pumps one of the most versatile and economical centrifugal pumps on the market.

Features:

• Flows to 120 gpm or 90 ft. TDH @ 60 Hz

• Non-metallic solution contact

• Deep-lift capability up to 25 feet

• Fast priming 18 feet in 90 sec.

• Capable of running dry without damage

• Powerful rare earth magnets Provide sure coupling

• Accepts standard motors NEMA or IEC metric

Material:

PP, PVDF

performance:

10-120 gpm

SERIES ‘TM’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

The Series ‘TM’ magnetic coupled centrifugal pump directly addresses the weaknesses of other magnetic drive pumps. From high torque compact magnets to a large diameter reduced length shaft to massive precision finished thrust bearings, the ‘TM’ pump is designed to excel where other pumps fail. Heavy walled voluted casings improve pump strength, internal shaft support, chemical resistance, pressure and temperature capabilities as well as hydraulic efficiencies. Standard models are non-overloading with stated elevated specific gravity liquids

Features:

• Flows to 130 gpm or 68 ft. TDH @ 60 Hz (409 LPM or 14.4m @ 50 Hz)

• Non-metallic solution contact PP or PVDF pump Choice of EPDM or FKM elastomers

• High torque magnets To 1.5 S.G. with standard models

• Massive thrust bearings

• Heavy walled voluted casings for higher temperature applications

• Centrifugal, quiet, vibration-free

• Seal-less, leak-free magnetic coupled

• For use with standard NEMA or IEC ‘C’-face motors

Material:

PP, PVDF

Performance:

20-140 gpm

SERIES ‘UC’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

Series ‘UC’ magnetic coupled pumps are seal-less, ANSI dimensional, ETFE lined pumps that are specifically designed for corrosive chemical applications in a wide range of industrial services. The Series ‘UC’ pump is engineered to provide the utmost in reliability and longer pump life in even the most extreme applications. All wetted surfaces are non-metallic to provide superior chemical resistance. The Series ‘UC’ pump has a tough ductile iron casing bonded with a pure Tefzel (ETFE) lining. The enclosed impeller and pump liner are precision molded from carbon fiber reinforced ETFE while the pump liner also has an external containment shell of glass reinforced vinyl ester for optimum pressure resistance. The dual impeller bushings, shaft and front and rear thrust rings are sintered silicon carbide. The impeller thrust ring is manufactured from Fluorosint. These components provide exceptional chemical resistance and wear characteristics at all flows.

fEATURES:

• Flows to 330 gpm or 320 ft. TDH @ 60 Hz

• Non-metallic solution contact ETFE

• Up to 250°F applications

• ANSI dimensional

• Powerful rare earth magnets

• Magnetic coupled for leak-free pumping

• Accepts standard motors NEMA or IEC metric

Material:

ETFE lined

Performance:

25-330 gpm

SERIES ‘Z’ CENTRIFUGAL MAGNETIC COUPLED PUMPS

Specifications

Series ‘Z’ Magnetic Coupled Pumps are the latest in magnetic coupled pump technology. Tested and proven design features provide a pump that is sealless and leakproof. Available materials of construction and flow capacity to 145 gpm make this pump an excellent choice for a wide variety of applications. Standard ‘Z’ models have strong magnets, allowing them to provide continuous flow with liquids up to 1.1 specific gravity. Trimmed impellers allow continuous flow with liquids to 1.9 specific gravity. Durable and corrosion resistant construction of PP or ETFE ensures efficient and reliable performance for even the most critical applications. Standard TEFC motors, strong magnets and highly efficient impellers provide a quiet and efficient pump designed for years of trouble-free operation.

fEATURES:

• Flows to 145 gpm @ 60 Hz (548 LPM @ 50 Hz)

• Non-metallic solution contact PP / FKM or ETFE / FKM

• Powerful magnets

• Seal-less pump provides zero leakage and low friction for energy efficiency

• High efficiency closed impellers

Material:

PP, PVDF

Performance:

20-140 gpm

Self Priming Pumps

SERIES ‘G’ SELF PRIMING PUMPS

Specifications

The self-priming Series ‘G’ Pump is made in either Noryl or PPS, providing a maximum range of chemical resistance. It is available with SS 316, internal hardware or completely non-metallic solution contact. The pump comes standard with 304 stainless external hardware. The pump is protected with a basket-type strainer in either PP or ECTFE. The large cover makes initial priming and removal of the strainer quick and easy. The cover is the same material as the pump or it can be ordered in clear Lexan (PCN 64-1818 90). A PP baseplate is included with close-coupled electric drive pumps.After initial prime, the Series ‘G’ Pump will lift up to 15 vertical feet (4.6m) and will remain primed even after shutdown. This pump also features an open, non-clogging impeller which is molded in conjunction with the shaft sleeve, thus isolating the shaft from solution contact. The self-priming ability, chemical resistance, light weight and basket strainer make this an ideal pump for chemical transfer, waste treatment, emergency/backup or filtering.

Features:

• Flows to 100 gpm or 73 ft. TDH @ 60 Hz (315 LPM or 15m @ 50 Hz)

• Noryl or PPS construction with SS316 internal hardware

• Non-metallic solution contact available

• Will reprime to 15 feet (4.6m)*

• Close coupled – electric motor driven

• Shaft sleeve is same material as pump Isolates pump shaft from solutions.

• Combination 2″ O.D. MNPT x 1 1/2″ I.D. FNPT connections

Material:

Noryl, PPS – Plastic

Performance:

10-100 gpm

SERIES ‘S’ SELF PRIMING PUMPS

Specifications

The Series ‘S’ Self-Priming Centrifugal Pump is a chemically resistant pump for general service on water, salt water, mild acids and bases. It is offered in a choice of glass reinforced polyester, PP or PPS construction to provide a maximum range of chemical resistance. It is available with a choice of elastomers and SS 316 internal hardware or with completely non-metallic solution contact. The pump comes standard with 304 stainless external hardware. All pumps include a built-in check valve and feature a self-cleaning double volute which allows the Series ‘S’ pump to self prime and lift to 25 ft. The self priming capability and chemical resistance make this an ideal chemical transfer, waste treatment, and emergency / backup pump.

Features:

• Flows to 270 gpm or 120′ TDH

• Choice of materials – glass reinforced polyester, PP or PPS with SS316 internal hardware

• Non-metallic solution contact models available

• Will reprime to 25 ft. (7.6m) vertical

• Close-coupled to electric motor, gasoline engine, hydraulic, pneumatic drive

• Built-in check valve

• BSP threads available on polyester models

Material:

PP, PPS, PE- Plastic

Performance:

20-225 gpm

SERIES ‘I’ SELF PRIMING CENTRIFUGAL PUMPS

Specifications

Series ‘I’ Self-Priming Centrifugal Pumps are constructed with SS 316 housing, fiberglass reinforced polyester, PP, or PPS internals, EPDM, Buna-N or FKM elastomers, SS 304 external hardware and quick release clamp. All pumps include a built-in check valve, and a double flush volute. Series ‘I’ pumps are close-coupled to gasoline engines; or electric, hydraulic and pneumatic motors to fit most power requirements. They may also be pedestal mounted for long coupling to electric or gasoline drivers; or for flexible coupling to the user’s driver. This lightweight, self-priming pump provides corrosion resistance and efficient performance for a wide variety of water and corrosive liquid applications. CLOSE COUPLED PUMP with ELECTRIC, HYDRAULIC or PNEUMATIC DRIVE Pump with SS 316 housing, PP internal parts, SS 316 housing clamp, SS 316 internal fasteners, and EPDM elastomers. Pump includes PP baseplate on close coupled electric models, steel baseplate on close coupled hydraulic and pneumatic models. Motor shafts are extended with SS 316 shaft adapter. Pumps available with FKM elastomers, pedestal mounted, or long coupled.

Features:

• Corrosion resistant materials SS casing, fiberglass reinforced polyester, PP, or PPS

• Suction lift to 20′

• Flows to 170 gpm or 75′ TDH

• Dual ports 1-1/2″ and 2″, NPT or BSP

• Built-in check valve and double flush volute

• Close-coupled, long coupled or pedestal mounted

• Gasoline engine, electric, hydraulic or pneumatic motors

• Wetted metallic components are SS 316

Material:

SS304, PP, PE, PPSMetal/plastic

Performance:

15-150 gpm

SERIES ‘SP’ SELF PRIMING PUMPS

Specifications

Self-priming Series ‘SP’ pumps are constructed of cast iron for dependable duty in a variety of applications.

The pumps include a SS 316 shaft, SS 316 fasteners, synthetic fiber gaskets and cast iron mounting bracket. They feature a semi-open impeller which is also constructed of SS 316. Motors are standard NEMA 56C face, 3450 RPM @ 60 Hz or 2850 RPM @ 50 Hz, TEFC. After initial prime, the Series ‘SP’ pump will lift up to 20 vertical feet (6.1m) and will remain primed even after shutdown. The self-priming ability, along with compact design, make Series ‘SP’ pumps ideal for chemical transfer, waste water treatment, emergency/backup or filter pumping.

Features:

• Flows to 142 gpm or 90 ft. TDH @ 60 Hz (448 LPM or 19.1m @ 50 Hz)

• Cast iron – stainless fitted construction

• SS316 impeller (semi-open design)

• Replaceable SS 316 stub shaft

• Will reprime to 20 feet (6.1m)

• Back pull-out design

Marerial:

Cast iron – Metal

Performance:

20-140 gpm

SERIES ‘T’ SELF PRIMING PUMPS

Specifications

Series ‘T’ Self-Priming Centrifugal Pumps are lightweight, chemically resistant pumps for general service on water, salt water and mildly corrosive liquids containing solids. They will pass a solid 1/3 the diameter of the suction port. ‘T’ Pumps feature tough non-metallic impeller, steel volute and wearplate with non-metallic coating, SS 316 internal fasteners and SS 304 quick release housing clamp. Housing is rugged glass reinforced polyester. Pressurized oil lubrication system protects hard silicon carbide shaft seal faces. O-Rings and gasket are Buna-N. Engine driven pumps include spring mounted base rails. All pumps include a built-in check valve, feature easy servicing and during pumping, a self-cleaning double volute keeps pump free of settled solids.

fEATURES:

• Materials – Pump casing made of rugged glass reinforced polyester Buna-N elastomers and SS fasteners

• Flow rates electric motor driven to 380 gpm or 88 ft. TDH @ 60 Hz (To 1198 LPM or 18.6m TDH @ 50 Hz)

• Flow rates gasoline engine driven to 360 gpm or 83 ft. TDH (To 1360 LPM or 25.3m TDH)

• Will lift 25 ft. (7.6m) vertical*

• 2″ or 3″ PORTS

Material:

PP, PPS, PE – Plastic

Performance:

50-350 gpm

AIR OPERATED DIAPHRAGM PUMPS

Specifications

Here is a line of remarkably rugged and durable self-priming, double diaphragm pumps. Lube-free and non-stalling, all models will handle any product that pours, from clear water to highly viscous, abrasive and chemically aggressive materials. Proven to handle suspended solids and abrasives without damage to the product or the pump. The unique pump design utilizes far fewer parts than other pumps on the market. This results in longer operating life and easier maintenance at a lower cost. Since these pumps are driven by compressed air, there is no need for shielded electrical connections or explosion-proof motors. All models can run dry because there are no close fitting or sliding parts in the fluid section. Flow rates can be controlled to produce from zero to maximum flow simply by increasing or decreasing air flow or pressure.

Features:

• Wide selection of materials: SS, PP, AL, K, NSS – Conductive nylon N – Nylon

• 1/4″ – 2″ sizes – flows to 150 gpm

• Patented lube-free air system

• Will not stall at slow speeds

• Self-priming

• Runs dry

Material:

AL, PVDF, PP, SS316, Nylon

Performance:

1-150 gpm

SERIES ‘AA’ ‘B’ & ‘C’ METERING PUMPS

Specifications

INTERNAL CONTROL, Series AA1, B1, C1

These pumps offer the versatility of independently adjustable stroke length and stroke frequency, allowing dual manual control of pump output.

SERIES ‘AA’ .006 GPH to 2.0 GPH (.38 to 126 ml/M)

Series AA_4, AA_5 and AA_6 provide output ranges of 100:1.

Series AA_7 and AA_8 offer output ranges of 66:1.

SERIES ‘B’ and ‘C’ .008 GPH to 25 GPH (.05 to 1578 ml/M)

Series B and C provide output ranges of 100:1.

Features:

• Wide model selection, Capacities to 25 GPH, Choice of control options, Standard and optional liquid ends to meet any application

• Encapsulated electronics Pump electronics are enclosed in housing of corrosion- resistant PP, protecting the pump from spilled chemical and corrosive atmosphere.

• Pump status LED Provides visual indicator of pump operation

• Capable of handling – Acids Soaps Wetting Agents Caustics Brighteners Inhibitors Flocculents Detergents Filter Aids Chlorine Dyes … and many more

• Inherent pressure relief Should the back pressure exceed the strength of the magnetic force developed by the power coil, the pump will stop stroking, preventing any damage and eliminating the need for a pressure relief valve.

• Low maintenance – One moving unit, the armature-diaphragm assembly. No lubrication required. Modular construction provides easy replacement of components and major assemblies.

Material:

PP

Performance:

.006-25 GPH Metering

CARTRIDGE FILTER CHAMBERS

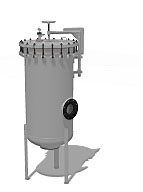

SERIES ‘K’ CARTRIDGE FILTER CHAMBERS

Specifications

The Series ‘K’ Metal Filter Chambers provide excellent value and are available in either a cartridge or bag design and with a choice of carbon steel, 304 or 316 stainless steel construction. Cartridge chambers range in size from a single 10″ cartridge to 448-10″ cartridge capacity. Bag chambers are from 0.5 sq. ft. to 26.4 sq. ft. of surface area. These chambers are ideal for either re-circulatory or single pass filtration in either series or parallel flow configurations. The wide range of sizes, styles and options means that due to chemical compatibility or temperature considerations require a metal filter chamber.

Features:

• Carbon steel or stainless steel construction

• EPDM elastomers standard (Viton® optional)

• Swing bolt cover closure with eye nuts

• 300 PSI pressure rating (single) 150 PSI pressure rating (3-round and 6-round)

• 316 SS internals

• Differential, drain, and vent ports

• Adjustable support legs

• 2-part epoxy finish on carbon steel

Material:

SS ST

Performance:

Very’s depending on unit. Click image for more information.

SERIES ‘L’ PLASTIC FILTER CHAMBER

Specifications

Flow rates up to 34 gpm depending upon style and length of filter cartridge, solids content, viscosity, pressure drop, size of connection and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered.

Features:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings to 160 psi

• Clamp ring closure or optional external tie rod

• Variety of sizes

• Port sizes 3/4″ and 1″ NPT

• O-ring seal at cover & vent valve

• Easy servicing, no tools required

Material:

CPVC, PVC, PP, PVDF

Performance:

1-40 gpm

SERIES ‘S’ PLASTIC FILTER CHAMBER

Specifications

These filter chambers are designed for filtering process solutions where clarification will extend operating life and improve quality.

• Depth wound, pleated, carbon or membrane cartridges

• Positive cartridge seal for: DOE (optional – SOE for 222 O-Ring)

• Cleanable sleeves (used with or without precoat) Flow rates up to 68 gpm depending upon style and length of filter cartridge, solids content, viscosity, pressure drop, size of connection and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered.

fEATURES:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings up to 135 psi

• 0-60 psi pressure gauge, mounted on a gauge guard

• Integral shell-base assembly

• Inlet to outlet at 90° or 180° aspect

• Variety of sizes are available From 3 to 15 of 10″ cartridges

• Port sizes 1NPT

Material:

PVC, CPVC, PP, PVDF

Performance:

3-75 gpm

SERIES ‘G’ PLASTIC FILTER CHAMBERS

Specifications

Flow rates to 125 gpm depending upon size of chamber, style of filter cartridge, solids content, viscosity, pressure drop and degree of clarity desired. Pressure ratings of filter chambers depend upon the temperature of solutions being filtered. All chambers have cover swing bolts with tee handles, SS swing bolt and hold down brackets; cartridge guides with screw-on cap, 0-60 psi pressure gauge with gauge guard, EPDM gaskets and drain plugs. All fasteners are SS. For use with DOE (Double Open End) cartridges

Features:

• Non-metallic solution contact CPVC, PVC or PP

• Heavy duty construction

• Pressure ratings to 80 psi

• Positive O-Ring seal at base and cover

• Cartridge guides with screw-on caps

• SS external hardware

• 0-60 psi pressure gauge with gauge guard

• From 12 to 60 – 10″ cartridge capacity

• Easy service Swing bolt cover closure

• Port size 1 1/2NPT or optional BSP

Material:

PVC, CPVC, PP

Performance :

12-125 gpm

SERIES ‘HD’ PLASTIC FILTER CHAMBERS

Specifications

SERIES ‘HD’ filter chambers are precision CNC machined from high purity PVDF or natural pure PP.

Chambers feature a swing bolt cover closure with ‘T’-handles for ease of cartridge service no tools are required. Precision machined covers feature FRP reinforcing plate to ensure positive liquid containment. Standard 0 – 60 psi gauge guard, vent valve and drain port are designed to simplify operation and maintenance. Standard flange connections are 1 1/2″ with rugged SS 316 back plates for ease of installation and to ensure leak-free operation. All external fasteners are SS 316; standard elastomers are EPDM. Chambers are designed for use with 4 – 10″, 20″, 30″ or 40″ SOE style filter cartridges.

Features:

• High purity non-metallic solution contact

• Proven durability and ease of service

• Standard heavy duty flange connections

• 0-60 psi gauge, air vent valve and drain port

• For use with standard 10″, 20″, 30″ or 40″ single open end (SOE) 222 style filter cartridges

• Flow rates to 150 gpm

Material:

PP, PVDF

Performance:

4-150 gpm

SERIES ‘HF’ PLASTIC FILTER CHAMBER

Specifications

SERIES ‘HF’ chambers feature precision CNC machined base and cover. The innovative base design has 3″ inlet and outlet ports providing low pressure differential. Base includes a 1″ plugged drain port for ease of maintenance. Cover includes vent valve, 0-60 psi pressure gauge with guard assembly, and SS cover plate. Cover is secured with swing bolts and ‘T’-handles (no tools are required to change cartridges). Shell is 18″ diameter and will hold 26 – 20″, 30″, 40″ or 50″* D.O.E. (double open end) style cartridges. Internals included are CPVC cross posts and PP cap springs to ensure proper cartridge location and eliminate solution bypass. Base, shell and cover are PVC for totally nonmetallic solution contact. Elastomers are EPDM and all external hardware is SS.

Features:

• Rugged construction, non-metallic solution contact

• Flows to 400 gpm

• High capacity – 26″ filter cartridges

• Standard 0-60 psi gauge with guard

• Low pressure drop – 4 psi @ 200 gpm

• ‘T’-handle cover closur

Material:

CPVC

Performance:

26-400 gpm

SERIES ‘GH-HP’ PLASTIC FILTER CHAMBERS

Specifications

For use with a variety of filter media (order separately)

– Depth wound, pleated, carbon or membrane cartridges

– Positive cartridge seal for:

Standard – DOE . . . Double Open End

Optional – SOE . . . Single Open End for 222 O-Ring

– Cleanable sleeves (used with or without precoat)

Features:

• Non-metallic solution contact

• Heavy duty construction

• Pressure ratings to 140 psi

• Tee handles – No tools required

• Pressure gauge with vent valve

• High Pressure and High Flow

• SS tie rod cover closure & SS bracket

• Variety of sizes, From 4 to 55 – 10″ cartridge capacity

• Port sizes 1 1/2″, 2″ & 3″

• Gasket seal at cover and base

Material:

PVC, CPVC, PP, PVDF

Performance:

5-300 gpm high psi

SERIES ‘Y’ STEEL FILTER CHAMBER

Specifications

24 To 445 Filter Cartridges Or 12 To 89 Cleanable Sleeves

SERIES ‘Y’ filter chambers are made of carbon steel with vulcanized rubber or Hypalon lining to provide non -metallic solution contact for use with a wide range of chemical solutions. Corrosion resistance in each case is limited to the materials used in construction, including all components. It should be noted that corrosion resistance varies at different temperatures. Consult Bulletin TC-101 and Sales Department. These chambers are ideal for in-line applications or they can be used with a pump and motor filtration system for various chemical applications.

Features:

• Non-metallic solution contact Rubber or Hypalon lined, steel construction

• High flow rate – up to 10 G PM perfilter tube as applicable

• Large dirt holding capacity From 84 to 1557 sq .ft. w/ cartridges or 14 to 267 sq.ft. w/sleeves

• ASME code design – optional

• Weld ed construction

• Cartridge or precoat filtration

• Removable cage asse mbly Easy to service

• Flanged inlet, outlet and vent ports

Material:

Steel Rubber lined

Performance:

24-450 gpm

SERIES ‘GC’ PLASTIC FILTER CHAMBERS

Specifications

These filter chambers are designed for filtering process solutions where clarification will extend operating life and improve quality. Series ‘GC’ chambers feature a precision CNC machined base and molded cover. The innovative base design has 2″ inlet and outlet ports providing low pressure differential. The base includes 3/4″ plugged drain ports for ease of maintenance. The shell is cemented to the machined base to eliminate leakage and warping.

Features:

• Non-metallic solution contact

• Heavy duty construction

• High flow rate, low pressure drop 2″ connections

• High capacity 12 of 20″, 30″, 40″ or 50″ cartridges

• Easy to operate – swing bolts with ‘T’-handles

• 60 psi gauge, air vent valve and drain port

Material:

PVC, CPVC

Performance:

12-200 gpm

Bag Filter Chambers

SERIES ‘L’ BAG FILTER CHAMBERS

Specifications

The Series 410 – 430 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers provide surface area of 0.75 to 2.25 sq. ft. and are designed for small tanks or small filtration applications. The 410 – 430 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The design is based on our proven ‘L’ chamber with molded base and cover and clamp closure. Depending on the application and the solution being filtered, these chambers are capable of handling 100 PSI pressure at ambient conditions and 200 F at lower pressures. Because of their size, these chambers can provide a more economical solution for smaller filtration applications.

Features:

• Non-metallic solution contact PVC, CPVC, PP or PVDF construction EPDM elastomers standard (FKM optional)

• Sizes to 2.25 square feet (0.23 sq/m) For flow rates to 20 GPM (75 LPM)

• Top inlet – bottom outlet design

• Easy to service Clamp ring cover closure – No tools required

• Port size 3/4″ hose quick-connect coupling x 3/4FNPT

• PP filter bags 1, 5, 10, 25, 50 and 100 micron

Material:

PVC, CPVC, PVDF

Performance:

20 gpm

SERIES ‘S’ BAG FILTER CHAMBERS

Specifications

The Series 630 and 640 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers have been redesigned to make them easier to operate and more convenient to service. The new design features a bottom inlet and bottom outlet which allows these chambers to be hard piped and allows the user to change bags without disconnecting any hoses or piping. Additionally the new employs easy to service swing bolt cover closure.

As before the Series 630 and 640 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The single bag design provides filter area to 5.0 sq. ft. and micron retention Ratings of 1 to 100.

fEATURES:

• Non-metallic solution contact

• Bottom inlet and outlet design

• Easy to service Swing bolt cover closure

• Port sizes 1 FNPT

• PP filter bags

mATERIAL:

PVC, PP, CPVC, PVDF

pERFORMANCE:

3.5 – 5 sq. ft., 40 gpm

SERIES ‘G’ BAG FILTER CHAMBERS

Specifications

The Series 1235 and 1255 Bag Filter Chambers are designed for filtering various process solutions where clarification will extend operating life and improve quality. These chambers have been redesigned to make them easier to operate and more convenient to service. The new design features a bottom inlet and bottom outlet, which allows these chambers to be hard, piped and allows the user to change bags without disconnecting any hoses or piping. Additionally the new design utilizes multiple 4″ flanged bags which provides greater surface area for the same size chamber. As before the Series 1235 and 1255 Bag Filter Chambers feature non-metallic solution contact and are offered in a choice of materials of construction to meet a wide variety of applications. The new design provides filter area to 19.5 sq. ft. and micron retention ratings of 1 to 100.

Feratures:

• Non-metallic solution contact

• Bottom Inlet / outlet design

• Easy to service

• Port size 1 1/2″ NPT

Material:

CPVC, PVC, PP

Performance:

12-19.5 sq ft, 80-100 gpm

STEEL AND STAINLESS STEEL BAG FILTER CHAMBERS

Specifications

Single Bag Chambers Housing lid has a 3-bolt swing closure with a vent port. Connections are as noted with standard side inlet and bottom outlet. Housing is supplied with two differential pressure ports to measure the differential pressure across the filter bag. A two-part epoxy finish is applied on the carbon steel vessels to maximize the life of the housing; stainless steel vessels are supplied with a satin finish. Basket material is constructed of 316 stainless steel with 9/64″ perforations to act as a strainer or to accept a liquid filter bag. Basket for KBS6 and KBS8 chamber seats onto an “O”-ring in the basket support.

Features:

• Carbon steel or stainless steel construction

• EPDM elastomers standard (FKM optional)

• Swing bolt cover closure with eye nuts

• 316 SS strainer basket

• Differential, drain and vent ports

• 2-part epoxy paint on carbon steel

Material:

ST, SS

GRAVITY FILTRATION systems

SERIES ‘DF’ GRAVITY FABRIC FILTRATION SYSTEM

Specifications

This system is totally automatic and responds to wide variations in flow rate and solids concentration. Pump the contaminated solution to the diffuser tray which distributes flow across the full width of the filter bed. Particle separation starts immediately via gravity flow through the media to the clean reservoir below the conveyor frame. Filtered solution can then gravity drain to waste or be returned to the process via a pump. Gravity flow allows gentle accumulation and settling of solids on the filter fabric. The concave configuration of the media bed accommodates the flow rate and maximizes solids loading on the fabric. As the media gradually becomes laden with solids, the solution level will slowly rise until the float switch activates the convey or drive motor. Consumed fabric is advanced to the sludge box as fresh media is simultaneously indexed to the solution flow.

Features:

• Unattended operation Automatically indexing media allows continuous filtration, even with varying input or solids content.

• Choice of materials Carbon steel, SS 316, CPVC or PP

• Sizes for any application From 1.5 to 113 sq. ft. of filter surface area Flow rates to 650 gpm @ 80 micron

• Low operating cost

Material:

ST, SS, CPVC, PP

Performance:

650 gpm

SERIES ‘DFS’ GRAVITY FABRIC FILTRATION SYSTEM

Specifications

This system is totally automatic and responds to wide variations in flow rate and solids concentration. Pump the contaminated solution to the diffuser tray which distributes flow across the full width of the filter bed. Particle separation starts immediately via gravity flow through the media to the clean reservoir below the conveyor frame. Filtered solution can then gravity drain to waste or be returned to the process via a pump.

Gravity flow allows gentle accumulation and settling of solids on the filter fabric. The concave configuration of the media bed accommodates the flow rate and maximizes solids loading on the fabric. As the media gradually becomes laden with solids, the solution level will slowly rise until the float switch activates the convey or drive motor. Consumed fabric is advanced to the sludge box as fresh media is simultaneously indexed to the solution flow.

Features:

• Unattended operation Automatically indexing media allows continuous filtration, even with varying input or solids content.

• Choice of materials ST or SS316

• Sizes for any application From 1.5 to 113 sq. ft. of filter surface area

• Low operating cost

Material:

ST, SS316

Performance:

2-646 gpm

Purification: Carbon and Resin Systems

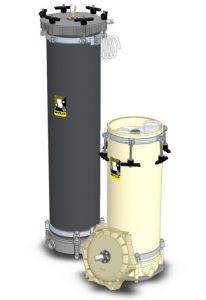

CARBON PURIFICATION SYSTEM

Specifications

Connect to your existing filtration system for continuous carbon treatment. Recommended installation provides side-stream flow through carbon for best control of results. One or two months of operation is not unusual before carbon change is necessary.

Features:

• Bulk Carbon Chamber for maximum amount of granular carbon

• Carbon Canister Chamber for convenient refill of granular carbon and interchangeability with C528PE or C548PE powdered carbon cartridges.

Material:

CPVC, PVC, PP

Performance:

13-84 lb. capacity

ION EXCHANGE RESIN CHAMBERS

Specifications

All ion exchange chambers / systems can be used with granular carbon. Precious Metal Recovery – These resin systems can recover gold and other metals from plating operations easily and economically. Select the proper resin for gold recovery from acid or cyanide rinse water. Depth of resin column assures good solution contact for maximum metal recovery. Gold is recovered by incinerating the resin. Units have early payback; one cubic foot of resin can retain 70 to 100 troy ounces of gold. Heavy Metal Removal / Recovery – Recover heavy metals from metal finishing rinse water and printed circuit board manufacturing. Effluent is suitable for discharge or bath replenishment. Concentrated regenerate can be chemically treated for disposal or possible recovery. Water Purification -Units provide high quality deionized water when fi lled with a strong base mixed-bed resin. Product water is low in dissolved solids, CO₂ and silica, with a resistivity of 10MΩ or higher. Resin has built-in resistance color indicator, changing from purple to golden brown to indicate resin exhaustion.

Features:

Non-metallic solution contact, Easy servicing without tools construction. Chambers are available in translucent PVC, PVC, or FRP (fiberglass reinforced polyethylene) shell, in sizes from 0.15 to 15 cubic feet of resin. Built-in strainers help prevent resin migration.

Material:

CPVC, PVC, PP